Choosing between a skid and a pallet might seem like a small detail, but the wrong pick can cost you time, damage freight, or inflate handling overhead across your warehouses and transport routes. In 2025, the U.S. wood-pallet and skid industry generated around US $20.7 billion in revenue, underscoring just how critical the choice of base is for supply-chain profitability and stability. By understanding the structural differences, safety risks, and cost-efficiency trade-offs, you can match the right base to your load and operations, saving money, improving uptime, and avoiding freight damage. Let’s dig into what separates a skid from a pallet, and which one may fit your workflow best.

Key Takeaways

Skids have a single deck and no bottom boards, making them ideal for heavy machinery, static loads, and low-budget, low-movement applications.

Pallets use top and bottom decks for balanced lifting and safe stacking, fitting warehouse racking, transport cycles, and high-touch workflows.

Skids cut cost and nest compactly but offer limited forklift access, while pallets support multi-direction handling and protect loads during transit.

The right choice comes down to movement frequency, load weight, equipment access, and whether durability or simple, stationary support matters.

What Is a Skid?

A skid is a single-deck platform built on runners that gives you a stable base for static or drag-based positioning. It works well when you need something durable without requiring full forklift access or stacking strength. Because it lacks a bottom deck, you benefit from lower cost, easier nesting, and simpler handling for stationary loads.

Once the skid is clear, it’s easier to understand how a pallet adds more structure for modern handling systems.

What Is a Pallet

A pallet is a two-deck platform designed for repeat handling, forklift entry, pallet jack access, and secure stacking within busy warehouse flows. You rely on pallets when your freight needs to move through racking systems, trucks, staging lanes, and automated equipment. Their standardization, load stability, and compatibility make them the preferred choice for most U.S. supply chains.

With both bases defined, the next step is comparing how they behave in real operations.

Key Differences Between Skids and Pallets

The difference between a skid and a pallet affects how you store, handle, and protect your freight throughout its journey.

Here’s a clear, skimmable breakdown:

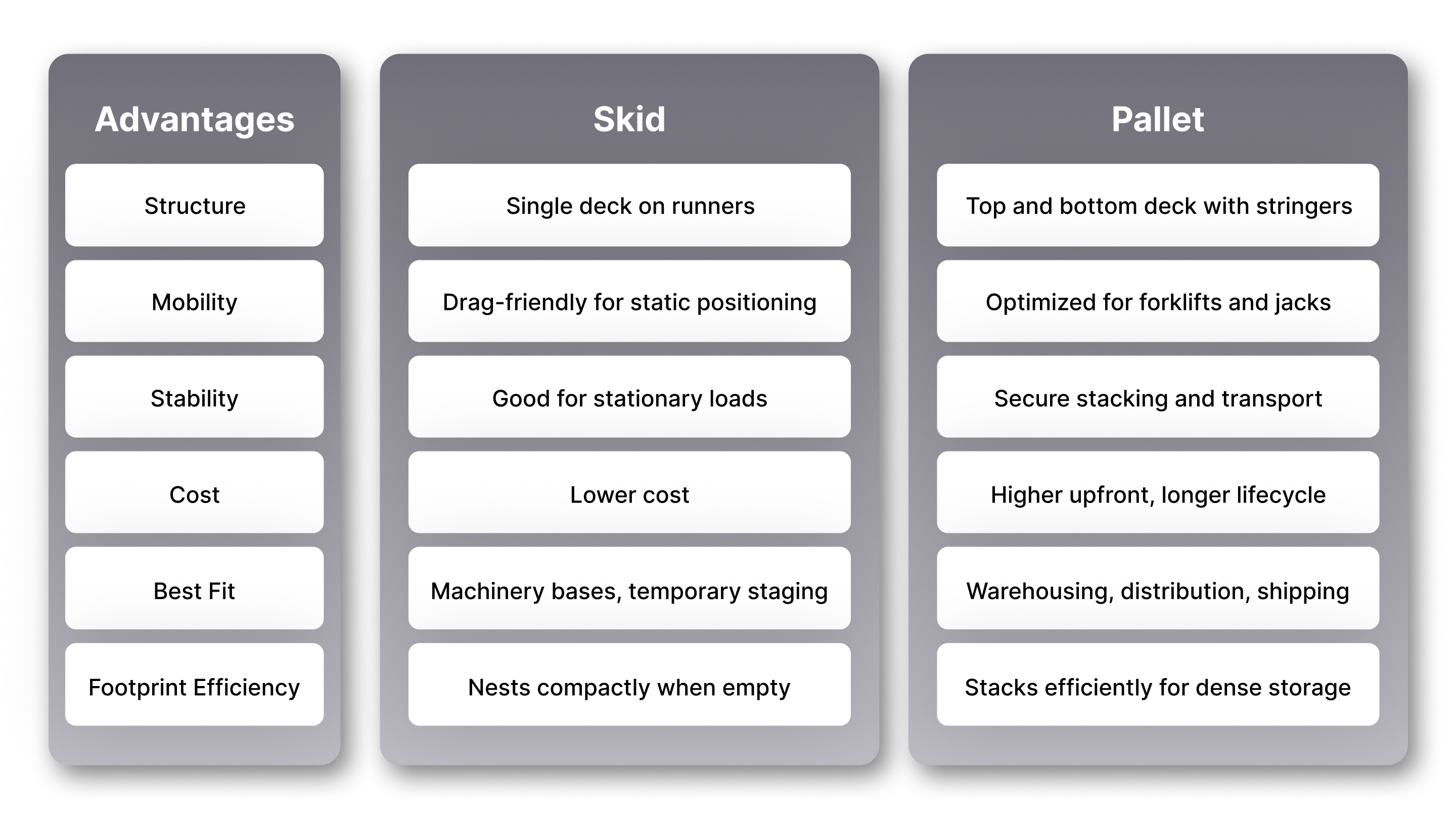

Factor | Skid | Pallet |

|---|---|---|

Structure | Single top deck on runners | Top and bottom deck with stringers or blocks |

Mobility | Drag-friendly for static positioning | Optimized for forklifts and pallet jacks |

Stability | Good for stationary loads; poor for stacking | Secure stacking and transport stability |

Cost | Lower cost and material use | Higher upfront but longer lifecycle |

Best Fit | Machinery bases, temporary staging | Warehousing, distribution, shipping |

Footprint Efficiency | Nests compactly when empty | Stacks neatly for high-density storage |

After looking at how they differ, design details help explain why each behaves the way it does.

Design Differences Between Skids and Pallets

Understanding the design differences between a skid and a pallet helps ensure each load sits on the right structure for safe handling and reliable performance.

Here’s a clear breakdown of how both bases differ in construction and functional design:

Design Element | Skid Design | Pallet Design |

|---|---|---|

Deck Structure | Single top deck with open underside, which reduces material usage and weight | Dual-deck format with top and bottom boards for load stability |

Base Support | Runners or “stringers” only, ideal for stationary or drag-based positioning | Blocks or stringers with full bottom support for balanced lifting |

Handling Access | Limited access points; works best when movement is minimal | Designed for pallet jacks and forklifts from multiple entry sides |

Load Behavior | Performs well for static, heavy, or anchored equipment | Maintains load stability during stacking, racking, and transport |

Space Efficiency | Nests tightly to conserve the empty storage footprint | Stacks uniformly for organized warehouse storage |

Durability Dynamics | Less reinforcement due to simpler construction, suitable for low-movement loads | Reinforced structure suitable for repeated cycles and transport demands |

Tip: When design differences matter for load stability, many teams rely on AAA GMA 48x40 pallets for consistent strength and standardized handling across mixed warehouse environments.

With the construction differences clear, it becomes easier to choose the right base for your specific workload.

Choosing Between a Skid and a Pallet

You’ll make the right choice by weighing load movement, equipment access, stability needs, and lifecycle value.

Here’s how to decide:

If your load doesn’t move often:

Use a skid when the freight stays put or only needs dragging.

Use a pallet if you anticipate future forklift handling.

If your load cycles through multiple touchpoints:

Choose a pallet for transport, stacking, staging, and racking.

Avoid skids here because instability increases damage risk.

If cost efficiency is your priority:

A skid helps you cut upfront spend for simple, low-movement loads.

A pallet delivers better long-term value when used repeatedly.

If your warehouse uses automation or standardized racks:

Stick to pallets for consistency and equipment compatibility.

Skids disrupt automation flows and cause inefficiencies.

If you’re optimizing sustainability and floor space:

Skids support nesting, reducing storage footprint.

Pallets enhance reusability and controlled material cycles.

After narrowing your choice, it helps to see how different industries put both bases to work.

Use Cases and Benefits

Your operations benefit when you match the right base to the right workflow. Here are the most relevant use cases and benefits:

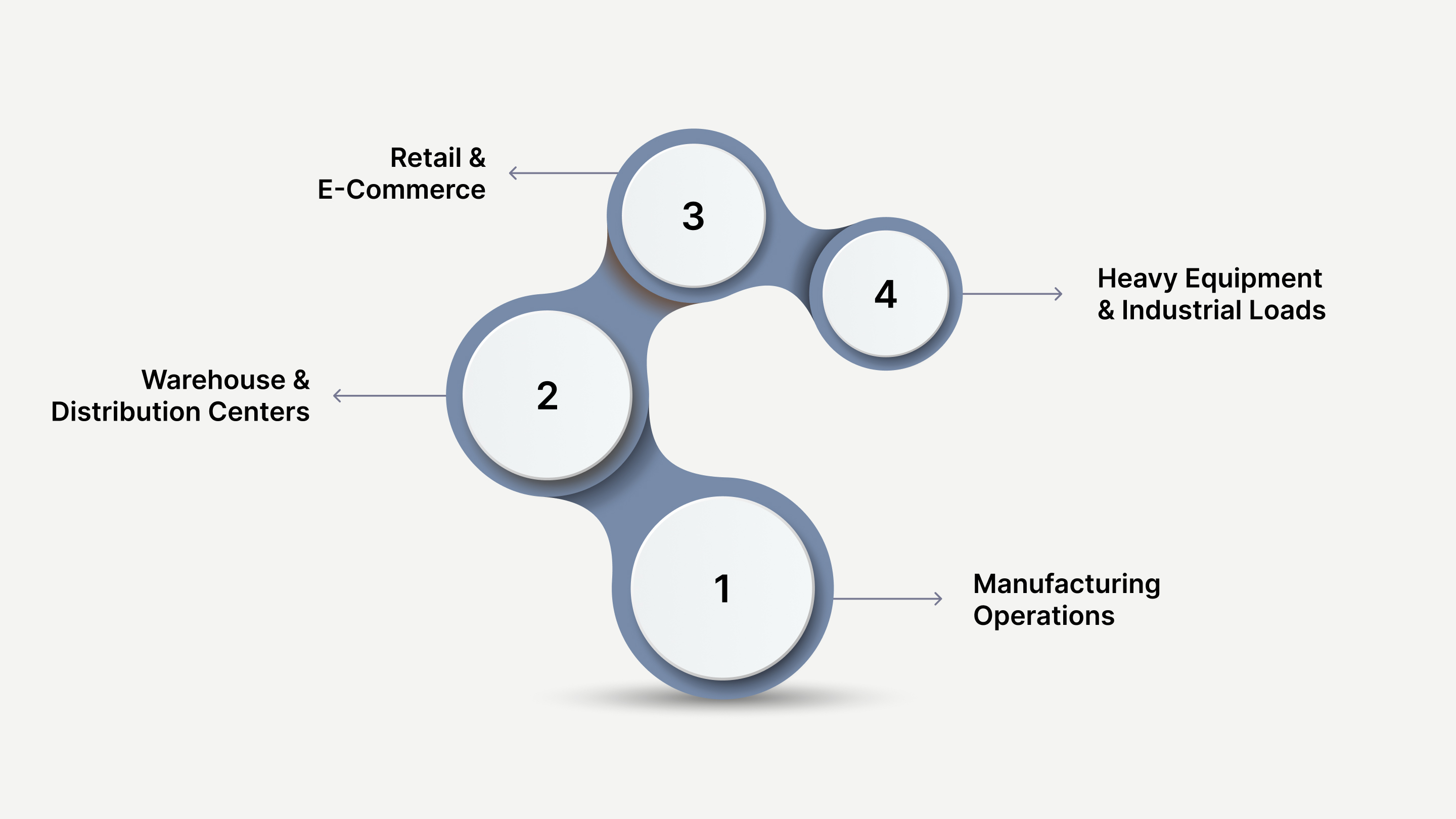

Manufacturing Operations

In manufacturing plants, skids often support heavy machinery or static components that rarely move and need a stable, low-cost base. Pallets handle outbound shipments, component transfers, and multi-stage handling when forklifts or pallet jacks are part of the route. This combination lets your team balance freight stability with smarter spending on pallet and skid usage.

Warehouse & Distribution Centers

Within distribution centers, pallets manage high-velocity movement, staging, and stacking across docks, aisles, and racking systems. Skids provide an efficient option for floor-level storage, oversized goods, or loads that don’t need structured handling. This blend helps your warehouse maintain throughput while controlling pallet spend and preventing unnecessary load handling, with reliable Grade A 48x40 pallets suited for fast-turn environments

Retail & E-Commerce

In retail and e-commerce workflows, pallets move fast-turn inventory through sorting zones, fulfillment areas, and outbound transport. Skids support bulky products, seasonal displays, or goods that stay staged without continuous lifting. This split keeps your pallet inventory optimized while allowing more flexibility in how each load is presented or stored.

Heavy Equipment & Industrial Loads

For industrial loads, skids create a stable foundation for stationary equipment that’s too heavy or inefficient to lift repeatedly. Pallets take over when heavy components still require forklift access, staging, or controlled movement within the facility. This approach reduces load-shift risk while protecting both your operators and handling equipment.

Even with the right use case in mind, base selection still goes wrong when certain details are overlooked.

Common Mistakes When Selecting Bases

Choosing the wrong base leads to freight damage, higher handling costs, and slower warehouse flow.

Here are the mistakes to avoid:

Using a skid for freight that requires frequent forklift handling or stacking.

Selecting a pallet when a simple static skid would have cut costs with no loss of performance.

Ignoring load weight, shape, or distribution when selecting between pallets and skids.

Using non-standard sizes that don’t fit racks, trucks, or automation paths.

Reusing damaged pallets or skids without inspection risks safety incidents.

Forgetting export requirements such as ISPM-15 heat treatment.

To reduce these mistakes across every facility, consider simplifying your workflow with Meridian’s Order Management Portal.

Preventing these issues becomes easier when you follow a few practical habits during loading and procurement.

Tips to Cut Costs and Avoid Shipping Damage

Staying intentional about how pallets and skids are selected, loaded, and handled helps reduce avoidable expenses and damage-related losses across your supply chain.

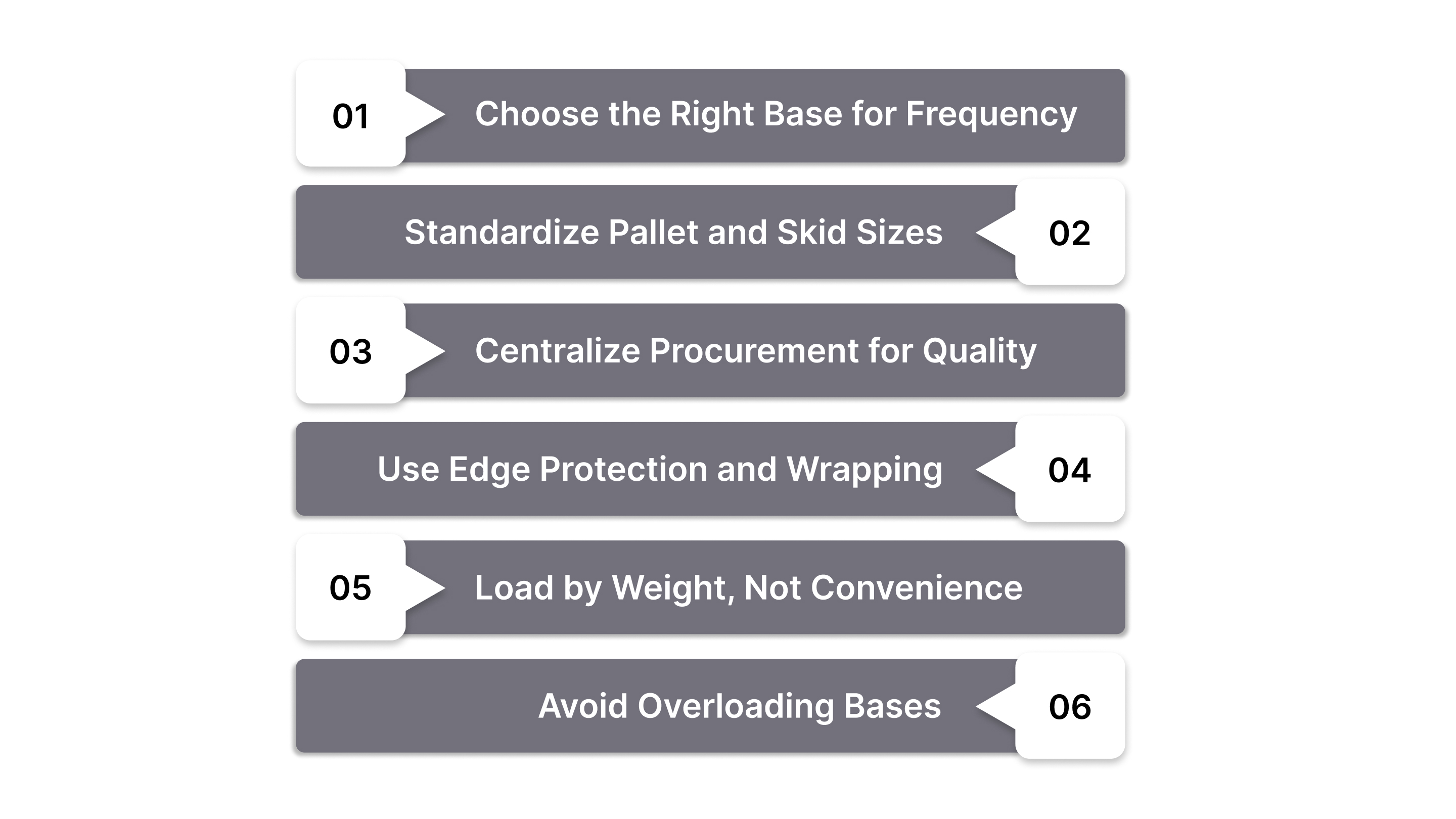

Here are practical, high-impact tips to apply:

Choose the right base for handling frequency: Skids work well for low-movement loads, while pallets offer safer handling for multi-stage transport and repeated forklift touches. Matching the base to the actual workflow prevents breakage, rework, and costly load instability.

Standardize pallet and skid sizes across all locations: Consistent sizing makes forklift handling safer, improves racking compatibility, and eliminates mixed-dimension freight that causes tipping or uneven stacking. Standardization also cuts procurement waste because orders consolidate into fewer SKU types.

Use a centralized procurement process to avoid inconsistent quality: Having one structured sourcing system reduces the risk of receiving mixed-quality pallets and skids from different vendors, which often leads to unexpected breakage or load failures. This approach keeps specifications consistent and helps maintain predictable freight performance.

Use edge protection and proper wrapping for fragile goods: Reinforced corners, stretch wrap, or strapping stabilize the load and reduce shifting during transit. Stable freight reduces insurance claims, chargebacks, and product loss.

Load by weight distribution, not convenience: Centered weight keeps pallets stable during lift, acceleration, and braking, while uneven placement increases the risk of collapse. Proper distribution is one of the fastest ways to prevent forklift-related damage.

Avoid over-capacity loading on either base: Exceeding recommended load limits, especially on lower-grade pallets or older skids, causes deck bowing and structural failure during movement. Staying within rated capacity protects both freight and equipment operators.

Once these best practices are in place, support from the right procurement partner can strengthen your entire freight-planning approach.

Meridian: Smarter Skid vs Pallet Decisions Start Here

Choosing the right base becomes far easier when your procurement, ordering, and supplier visibility are supported by real data and nationwide supply access.

Here’s how Meridian strengthens every freight decision:

Automated RFQ Platform: Submit RFQs in minutes, compare quotes from 2,400+ suppliers, and cut packaging and pallet spend by 5–25% using real-time market visibility.

Order Management Portal: Place and repeat orders with one click while tracking deliveries live, supported by a tiered backup network that maintains 99% uptime.

Procurement Insights Dashboard: View SKU-level spend, supplier performance, and commodity trends to plan purchases proactively, not reactively.

Packaging Optimization Audit: Gain guaranteed savings within 90 days through SKU clarity, redesign recommendations, and competitive nationwide RFQs.

Nationwide Pallet Supply: Access AAA, Grade A, Grade B, recycled, custom, and ISPM-15 options built near major U.S. markets for fast delivery.

Wrapping Up

Selecting between a skid and a pallet becomes far simpler once the structural differences, handling demands, and cost implications are clearly understood. With the right base supporting each load, your freight moves safer, faster, and with fewer preventable expenses across the supply chain. One partner that strengthens every part of this decision-making process is Meridian, offering data-backed procurement, nationwide supply access, and reliable pallet and skid solutions.

Ready to streamline procurement and cut pallet or skid spend? Contact Meridian today for your free U.S. spend analysis.

FAQ

What is the main difference between a skid and a pallet?

A skid has a single deck with runners, while a pallet has both a top and bottom deck for added stability. This structural difference affects how the load can be lifted, stacked, and moved.

Which is better for shipping heavy machinery?

Skids are typically preferred for heavy or stationary machinery because the single-deck design provides a stable base that stays put. Pallets become useful only when multiple lifting points or repeated handling are needed.

Are skids cheaper than pallets?

Skids generally cost less because they use fewer materials and have a simpler design. This makes them suitable for static storage or one-time moves where mobility is not a priority.

Can skids be used with forklifts?

Most skids can be lifted with forklifts, but access points are limited compared to pallets. This is why pallets remain the standard in environments requiring frequent lifting and handling.

Which option reduces the risk of freight damage?

Pallets usually offer better load stability during stacking, transit, and warehouse movement. Skids work well when loads stay stationary, but movement-heavy workflows often benefit from the structure of a pallet.