Heat-treated pallets represent a critical layer of protection in global logistics because they meet 2025 USDA-recognized ISPM-15 compliance standards. Controlling wood-packaging risks minimizes shipment refusals, unexpected quarantines, and operational breakdowns that strain procurement teams and budgets. Managing cost pressure becomes more realistic when pallet quality, durability, and SKU consistency reduce replacement cycles and prevent disruptions. Choosing heat-treated pallets strengthens long-term resilience by improving reliability while safeguarding compliance for any cross-border supply chain. This article breaks down what heat-treated pallets are, when they matter most, and how procurement teams can evaluate them effectively.

Quick Overview

Heat-treated pallets reach a 56°C core temperature for 30 minutes to meet ISPM-15 rules and prevent insect, mold, and pathogen transfer in global shipping.

Untreated pallets create measurable risks, including quarantine holds, fungal contamination, product damage from weakened boards, and limited traceability during inspections.

Treated pallets deliver stable load performance, cleaner contact surfaces for food and pharma items, reduced spoilage in long storage, and fewer failures during repeated handling.

They deliver the most value for export loads, heavy or high-density SKUs, returnable loops, climate-variable routes, and facilities operating under strict hygiene protocols.

What Heat-Treated Pallets?

Heat-treated pallets are wood units brought to a core temperature of 56°C for at least 30 minutes to meet ISPM-15 standards. This process stabilizes the wood, removes insects and larvae, and strengthens long-term durability beyond most untreated pallet options. Clean, chemical-free treatment makes them suitable for sensitive goods, including food, beverages, pharmaceuticals, and regulated materials. Compliance becomes easier to manage because every pallet carries a traceable ISPM-15 stamp with the facility, country code, and treatment details.

Now, it becomes easier to understand why untreated pallets regularly create operational setbacks, which is what the next section explains.

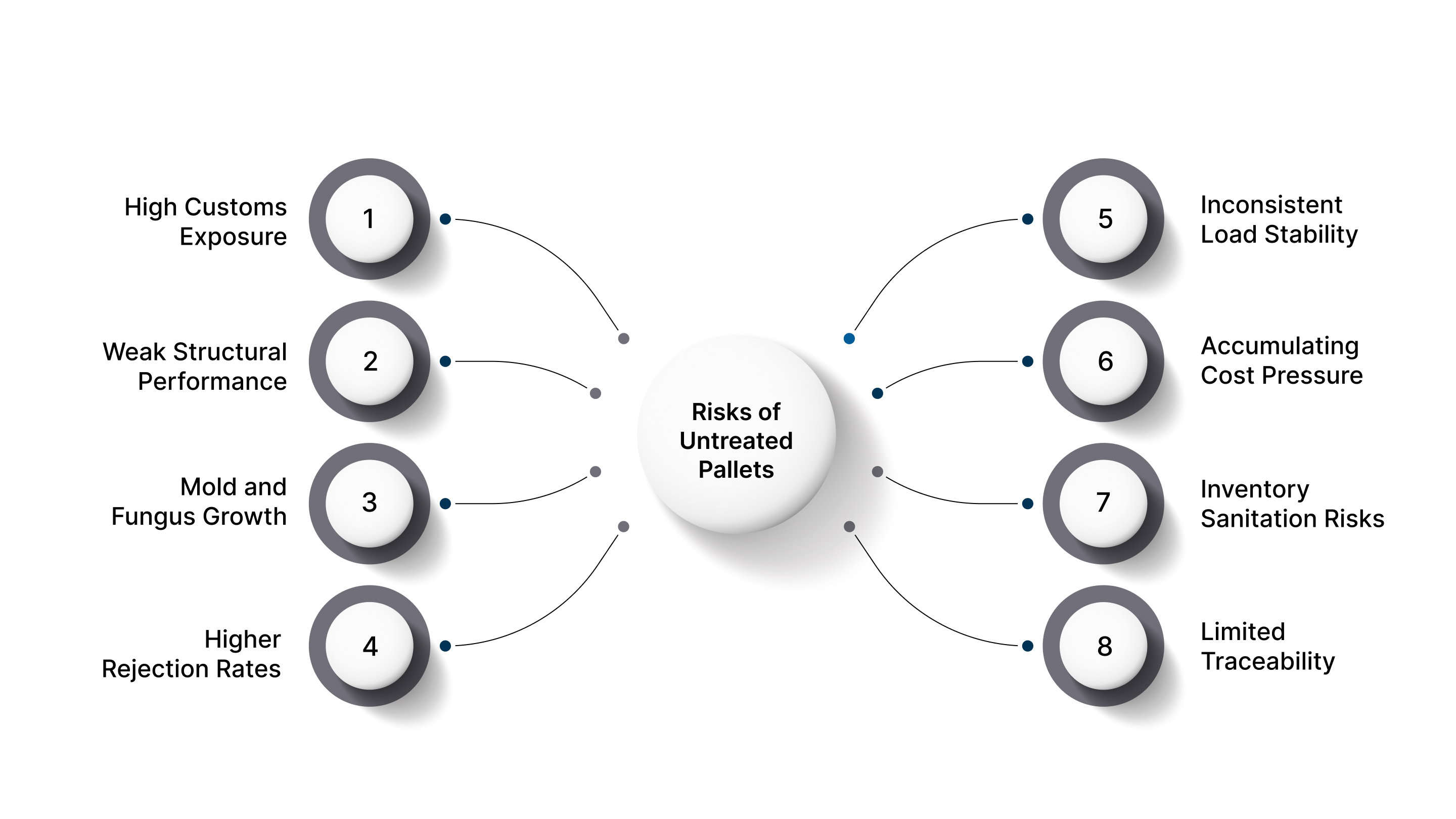

Why Untreated Pallets Create Risk?

Untreated pallets expose your operation to contamination, structural failures, and customs issues that compromise supply-chain stability. Here are the risks your procurement decisions help control:

High Customs Exposure: Untreated pallets trigger inspections, quarantines, and occasional destruction orders, pushing you into costly delays and rework.

Weak Structural Performance: Higher moisture levels weaken deckboards and stringers, increasing the likelihood of failures that damage your products.

Mold and Fungus Growth: Fungal activity forces receiving teams to reject shipments, leaving you scrambling for replacements.

Higher Rejection Rates: Facilities handling food or pharmaceuticals deny untreated pallets quickly, pushing your workflow off schedule.

Inconsistent Load Stability: Irregular moisture content affects weight distribution and creates handling problems that slow your team.

Accumulating Cost Pressure: Every replacement, diversion, and emergency purchase reduces your ability to manage procurement budgets effectively.

Inventory Sanitation Risks: Unprocessed wood increases the chance of pest transfer inside your facility, affecting long-term storage quality.

Limited Traceability: Lack of standardized marking makes compliance harder to prove when customs or regulatory teams request documentation.

Those risks are tied directly to global wood-packaging regulations, so it helps to understand the ISPM 15 rules that govern how pallets must be treated for international movement.

What Should You Know About ISPM 15 Rules?

ISPM 15 outlines the global treatment requirements that solid-wood pallets must meet to move across international borders without biosecurity issues. A clearer picture emerges once the rule is broken down into the practical details that influence your shipping and compliance process.

Approved Treatment Methods: Only heat treatment and methyl bromide fumigation are recognized under ISPM 15, with heat treatment preferred worldwide due to cleaner handling.

Mandatory Marking Format: Each pallet must display the ISPM-15 stamp with its country code, facility number, and treatment type so inspectors can validate compliance quickly.

Applies Only to Solid Wood: The regulation covers solid wood thicker than 6 millimeters, while materials like plywood and OSB are exempt from treatment.

Border Inspection Rules: Customs officers can stop, rework, or destroy loads when markings are missing, incorrect, or unreadable, which raises cost and slows down delivery timelines.

Documentation Expectations: Keeping supplier certificates or batch treatment records helps support audits and reduces compliance disputes.

Widespread Global Adoption: More than 180 countries enforce ISPM 15, which keeps compliant pallet shipments moving more consistently across international routes.

Once the compliance requirements are clear, it becomes easier to see how heat-treated pallets support daily operations beyond just meeting the rule.

Key Benefits of Heat-Treated Pallets

Heat-treated pallets improve durability, compliance, and hygiene performance, giving your operation a more reliable foundation for daily movement. Here are the benefits that help you directly:

Improved Structural Life

Heat treatment lowers internal moisture, allowing your pallets to hold their shape and strength across multiple trips. Stronger construction reduces breakage that would otherwise cause product loss or workflow disruption. Extended use cycles help you manage long-term pallet budgets with fewer surprises.

Global Compliance Coverage

ISPM-15-approved markings allow your pallets to pass through customs with fewer delays and less scrutiny. Verified treatment records simplify compliance reviews when internal teams or regulators request documentation. Reduced uncertainty shortens lead times and keeps international movements predictable.

Cleaner and Chemical-Free Handling

Heat treatment removes pests without fumigation chemicals, giving your team a safer and cleaner handling surface. Chemically neutral materials support industries where hygiene and contact safety are non-negotiable. Lower contamination risk allows your pallets to meet sanitation expectations consistently.

Lower Contamination and Spoilage Risk

Dry, stabilized wood reduces the growth of mold or mildew during long storage cycles or climate shifts. Cleaner pallet surfaces protect your products from environmental contamination that could affect quality. Stronger hygiene performance reinforces the integrity of your entire distribution chain.

Better Inventory Confidence

Consistent pallet quality gives your warehouse teams fewer surprises as they move, store, and load goods. Predictable handling performance supports efficient coordination between shipping, receiving, and production teams. Improved reliability reduces strain on your labor and transport schedules.

Meridian strengthens these advantages further by giving you consistent access to ISPM-15 heat-treated pallets sourced from a vetted nationwide supplier network.

Seeing how these pallets perform in real conditions helps you understand where they deliver the most value, which is why the next section focuses on situations where they make the most sense.

When Heat-Treated Pallets Are Worth It?

Heat-treated pallets provide the greatest value when your shipment routes, product requirements, or compliance targets demand stability and cleanliness. Here are the scenarios where heat-treated pallets support your operation best:

Export Shipments Under ISPM-15: Cross-border movement requires compliant pallets to prevent inspection delays that disrupt delivery plans.

High-Value or Sensitive Inventory: Items with strict hygiene expectations benefit from cleaner, treated wood surfaces you can trust.

Returnable or Multi-Trip Flows: Longer service life strengthens your cost control across repeated distribution cycles.

Variable or High-Moisture Environments: Stabilized wood withstands climate changes without warping, swelling, or weakening.

Facilities With Strict Sanitation Protocols: Quality checks run smoother when your pallets meet or exceed hygiene standards.

Product Lines With Low Tolerance for Contamination: Regulated categories depend on pallet cleanliness to maintain compliance.

Long-Term Storage Conditions: Treated pallets reduce the chance of mold growth in extended warehouse holding.

Heavy or High-Density Loads: Strengthened wood supports demanding SKUs that increase stress on deckboards and stringers.

Knowing where they fit best makes the comparison with fumigated pallets much clearer, especially when evaluating treatment methods side by side.

Heat-Treated vs Fumigated Pallets

Heat-treated pallets differ from methyl-bromide-fumigated pallets in process, safety, environmental impact, and long-term performance. Here is a comparison to help your procurement planning:

Factor | Heat-Treated Pallets | Methyl Bromide Fumigated Pallets |

|---|---|---|

Treatment Method | Heated to 56°C for ≥30 minutes | Gas infused with methyl bromide |

Safety Condition | No chemicals or residue | Requires ventilation due to chemical traces |

Environmental Impact | Low footprint and widely accepted | High impact and heavily restricted |

Durability | Strengthens wood and extends lifespan | No improvement to structural performance |

Compliance Reliability | Preferred across ISPM-15 regions | Accepted but discouraged in many markets |

Best Fit | Food, pharma, export logistics | Limited cases where HT is unavailable |

Product Safety | Supports clean handling | Can create odor or residue concerns |

A fair comparison naturally leads to the question of how to buy the right heat-treated pallets, and the next section outlines the checkpoints worth reviewing.

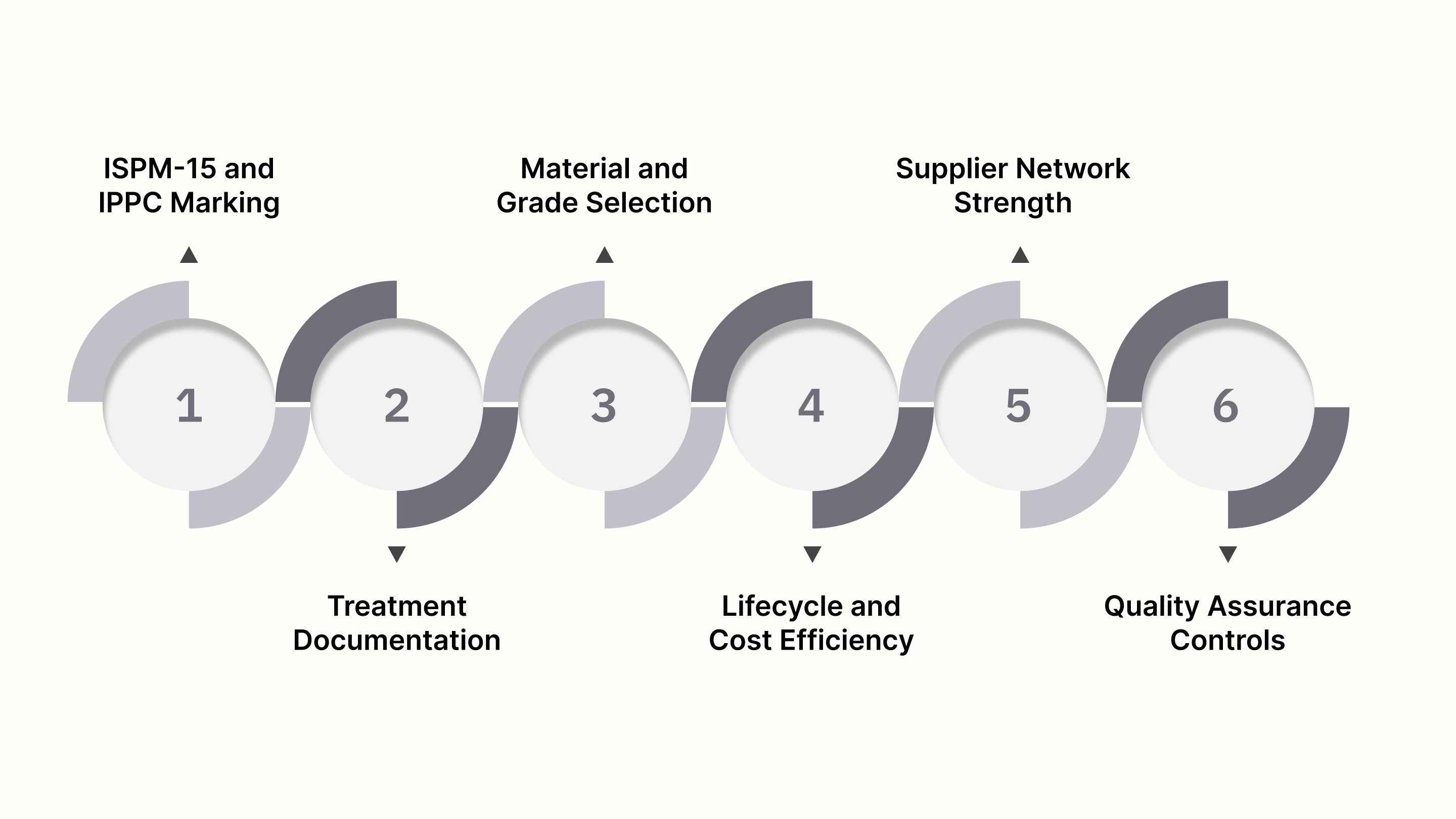

Buying Heat-Treated Pallets: What to Check

Purchasing heat-treated pallets requires clear verification of treatment, grade suitability, and supplier consistency. Here is what your evaluation process should include:

ISPM-15 and IPPC Marking

Stamps should show the country code, facility number, and “HT” mark clearly on two visible sides.

Reliable stamping reduces friction during customs checks and internal audits.

Treatment Documentation

Kiln logs and batch records confirm each pallet reached the proper temperature and exposure.

Verified documentation ensures your pallets meet both USDA and global requirements.

Material and Grade Selection

Board thickness, load capacity, and wood species should match your SKU weight and route distance.

Selection between new heat-treated pallets, recycled heat-treated pallets, or combo builds depends on your durability targets.

Lifecycle and Cost Efficiency

Longer use cycles offset higher upfront cost when measured against failure reduction and reduced product loss.

Total-cost modeling becomes easier when pallet lifespan is more predictable across your routes.

Supplier Network Strength

Suppliers with multiple treatment facilities support better continuity during peak volume periods.

Consistent production capacity ensures your orders remain reliable during demand spikes.

Quality Assurance Controls

Suppliers should follow structured inspection processes to maintain consistency from batch to batch.

Strong QA reduces the variance your teams encounter during receiving and handling.

An Automated RFQ Platform helps maintain consistent treatment standards and documentation so your heat-treated pallet sourcing stays dependable.

Once the buying criteria are clear, the final step is choosing a compliant and dependable source, which is why the following CTA highlights Meridian’s role without pressure.

Get Compliant Pallets Fast, Meridian’s Heat-Treated Solution

Meridian turns heat-treated pallet sourcing from a headache into a predictable, audit-ready process that saves money and time. Below are the ways Meridian directly helps when heat-treated pallets are part of your procurement plan:

Instant RFQs for heat-treated pallets: Submit exact ISPM-15 and pallet specs and reach 2,400+ verified suppliers in minutes.

Guaranteed 5–25% savings: Competitive bidding and nationwide sourcing lower your heat-treated pallet costs across all locations.

Verified ISPM-15 compliance: Access certified heat-treated pallets with proper stamping, documentation, and audit-ready records.

99% uptime with backup suppliers: Tiered heat-treated pallet partners prevent stockouts and shipment delays.

Real-time order tracking: Track heat-treated pallet production, transit, and delivery ETAs through the portal.

Next-day local delivery options: Heat-treated pallets sourced near your facilities reduce lead times and freight spend.

Spend and SKU clarity: Dashboard visibility shows your heat-treated pallet usage, pricing, and supplier performance across all sites.

Wrapping Up

Heat-treated pallets create predictable handling, stronger compliance, and cleaner transport conditions that protect your products and schedules. Better durability and lower contamination risk help your operation maintain consistency across domestic and international routes. Meridian supplies verified heat-treated pallets backed by nationwide delivery, strict quality controls, and reliable availability.

Secure compliant, ready-to-ship heat-treated pallets with guaranteed savings. Request your Meridian quote today.

FAQ

Do pallets need to be heat-treated for international shipments?

Most international routes require heat-treated pallets under ISPM-15 rules because untreated wood triggers inspections and potential rejection. Compliance reduces your risk of border delays and additional handling costs.

Are pallets heat-treated for domestic shipments?

Domestic shipping rarely mandates heat treatment unless internal standards require it. Selecting untreated pallets is acceptable for short-haul routes with low contamination risk.

What do heat-treated pallets mean in packaging?

A heat-treated pallet is a solid-wood pallet heated to remove pests, fungus, and moisture-related threats. This treatment strengthens your compliance posture and stabilizes pallet performance.

Can a pallet be heat-treated and methyl bromide fumigated?

Dual treatment is technically possible, though rarely justified because heat treatment alone meets global expectations. Additional fumigation increases cost without adding meaningful performance value.

Why use heat-treated pallets instead of regular ones?

Heat-treated pallets give your shipments cleaner handling, longer durability, and fewer compliance problems. These advantages help your operation maintain consistent tracking, sanitation, and delivery timelines.