In industrial and high-volume distribution environments, pallets are far more than basic transport platforms; they are critical load-bearing components that influence handling efficiency, freight cost, product protection, and operational safety. Yet one of the most critical factors affecting pallet performance is often overlooked: the type of wood used in their construction. Different wood species vary significantly in strength, durability, weight, moisture tolerance, and cost, which means the choice of pallet wood can directly impact supply-chain reliability and total cost of ownership.

This blog explores the most common types of wood used to make pallets, the differences between softwood and hardwood options, how pallet use cases determine material selection, and practical criteria to evaluate when choosing the best pallet wood for your operations. We’ll also look at how Meridian supports businesses in making informed pallet procurement decisions through its network, technology, and product solutions.

Here’s the short version

Most wooden pallets are made from softwood (such as pine or spruce) or hardwood (such as oak or maple), depending on load requirements and reuse expectations.

Softwood pallets are lightweight, cost-effective, and ideal for one-way shipping, export use, and lighter loads.

Hardwood pallets offer greater strength and durability, making them suitable for heavy industrial shipments and closed-loop reuse systems.

The right wood type depends on factors such as load weight, handling environment, compliance needs, sustainability goals, and total cost of ownership.

Businesses often overspend or underperform by choosing wood based only on upfront price rather than lifecycle performance and operational fit.

Meridian supports companies in selecting the optimal pallet wood through nationwide sourcing, standardized quality control, packaging optimization audits, and visibility into spend and performance.

Most Common Wood Species Used in Pallets

While wood availability varies by region, the pallet industry predominantly uses these species:

Softwoods

Wood Type | Key Characteristics | Best For |

Southern Yellow Pine (SYP) | Strong, lightweight, widely available, cost-efficient | Retail, light manufacturing, one-way shipments |

Spruce / Fir / Pine Mix (SPF) | Easy to kiln dry, lighter weight, consistent quality | Export pallets, compliance pallets |

Douglas Fir | Lightweight but strong | Construction & building materials distribution |

Hardwoods

Wood Type | Key Characteristics | Best For |

Oak | High strength & durability | Heavy manufacturing, automotive |

Maple | Dense & impact-resistant | Reusable shipping loops |

Ash | Flexible and shock-resistant | Industrial handling |

Birch / Poplar | Balance between strength & weight | Custom-engineered pallets |

Recycled Pallet Wood

Recycled or remanufactured pallets commonly use reclaimed hardwood or softwood components. They support sustainability goals and reduce costs, but quality control and inspection are essential.

Knowing the most frequently used species sets the foundation, but the bigger question is how these woods differ in real-world performance. That’s where the comparison between softwood and hardwood becomes essential.

Understanding the Difference Between Softwood and Hardwood Pallets

Choosing between softwood and hardwood pallets is one of the most important decisions in pallet procurement. While both wood types are widely used across industrial and commercial supply chains, they offer distinctly different advantages depending on application and lifecycle expectations.

Feature | Softwood Pallets | Hardwood Pallets |

Density & Strength | Lower | Higher |

Weight | Lighter | Heavier |

Cost | More affordable | More expensive |

Availability | Widely available | Regionally dependent |

Reuse Capabilities | Lower reuse count | High reuse count |

Ideal Uses | Export / light loads / single use | Heavy loads/return loops/warehousing |

When Softwood Is Best

Reduced freight weight matters

Shipments are single-directional or disposable

You require rapid production & consistent sourcing

Cost sensitivity is high

When Hardwood Is Best

High durability and structural reliability are critical

Loads exceed 2,500+ lbs

Pallets will circulate multiple times

You operate in the heavy industrial or automotive sectors

Even with a clear understanding of material differences, the right option ultimately depends on how a pallet will be used.

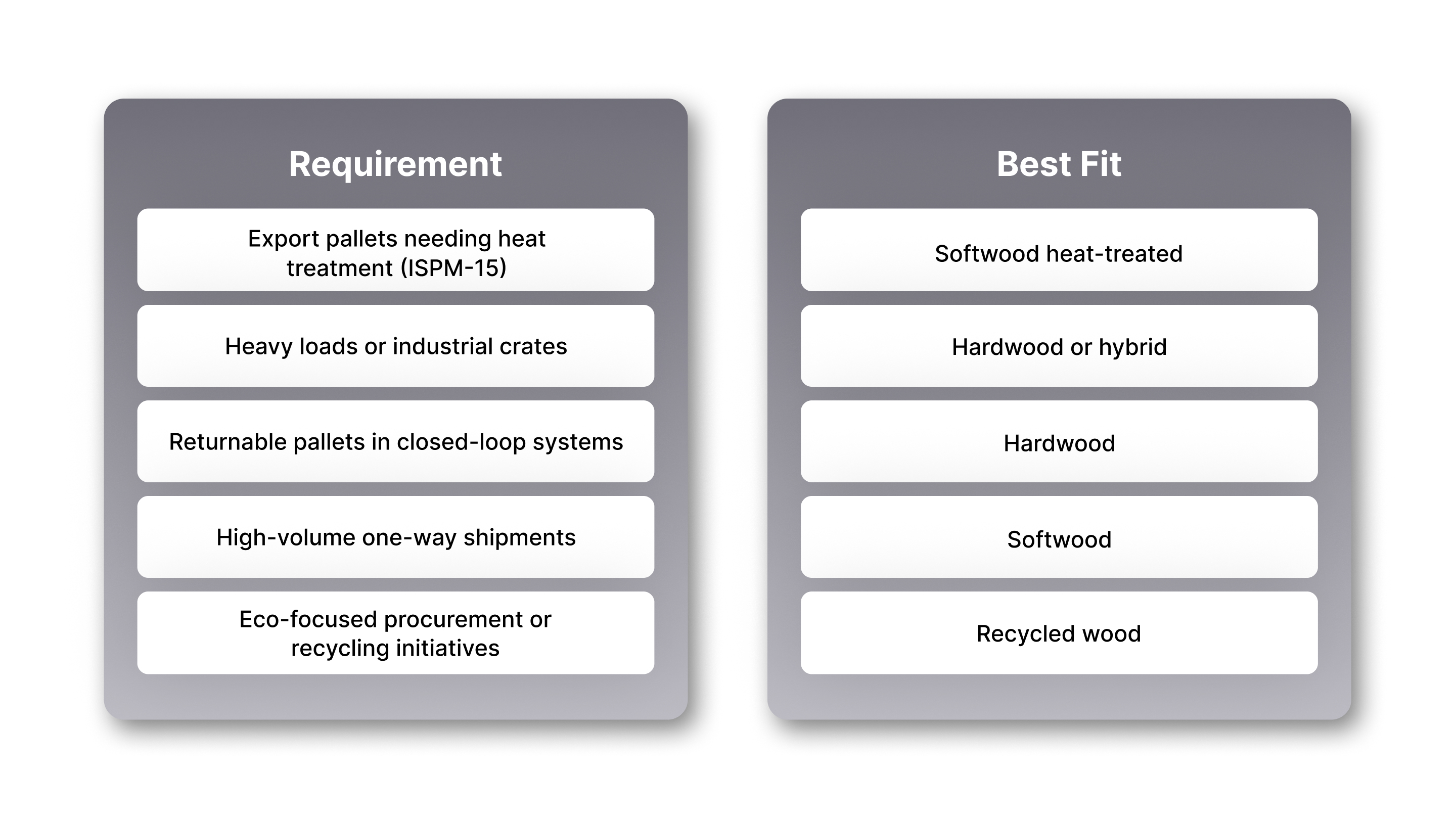

How Pallet Use-Case Determines Wood Choice?

A pallet designed for a single domestic shipment has very different requirements than one used in a closed-loop industrial system or for international freight. Evaluating pallet wood through the lens of real operational use cases ensures that performance, cost, and reliability remain aligned with business objectives.

Consider use-case priorities like:

Requirement | Best Fit |

Export pallets needing heat treatment (ISPM-15) | Softwood heat-treated |

Heavy loads or industrial crates | Hardwood or hybrid |

Returnable pallets in closed-loop systems | Hardwood |

High-volume one-way shipments | Softwood |

Eco-focused procurement or recycling initiatives | Recycled wood |

Industry examples

Retail & eCommerce: Lightweight softwood pallets keep costs low.

Automotive & Aerospace: Hardwood pallets prevent structural failure under large equipment loads.

Food & Pharmaceutical: Heat-treated softwood prevents pest contamination.

Logistics Networks: Mixed-species recycled pallets maximize sustainability.

To simplify the decision-making process, evaluate pallet materials using practical criteria that align with your specific handling, performance, and cost priorities.

How to Choose the Right Pallet Wood - A Quick Checklist

Before selecting pallet wood, evaluate:

☑ Key Decision Factors

Load weight & distribution

Expected number of trips/lifecycle

Transportation mode (road/sea /air)

Export regulations (ISPM-15 compliance)

Product sensitivity (moisture, hygiene, chemicals)

Storage conditions (indoor vs outdoor)

Sustainability goals/recycling

Budget vs total cost of ownership

Lead time & supplier availability

If more than two priorities compete (e.g., weight, strength, and cost), a hybrid approach or a customized pallet design may be ideal.

While the checklist supports informed internal decision-making, many businesses still struggle to balance cost, consistency, and supply reliability across multiple locations. This is where a strategic procurement partner can provide measurable value.

Why Meridian Is the Right Partner for Smart Pallet Procurement?

Choosing the right pallet wood isn’t just about lumber species; it’s a procurement decision that affects cost, quality, delivery reliability, and operational risk. Meridian helps companies make strategic pallet decisions by providing:

Why Meridian?

A nationwide network of 2,400+ pallet manufacturing partners

Access to all major pallet types: softwood, hardwood, recycled, heat-treated, and custom-engineered

Automated RFQ platform for transparent price comparison

Order Management Portal & real-time analytics dashboard

Packaging Optimization Audit to identify savings opportunities

High assurance of quality control & compliance across locations

Capacity to support multi-facility operations and fast delivery

Whether you need standard 48×40 GMA pallets, custom sizes, heavy-duty hardwood pallets, or export-approved heat-treated pallets, Meridian enables smarter pallet procurement and measurable cost savings.

Conclusion

There is no universal answer to which wood type is best for pallets; every supply chain has unique requirements based on load weights, handling frequency, transportation conditions, sustainability goals, and cost structure. Softwood offers lightweight affordability for high-volume or one-way shipping, while hardwood delivers the strength and longevity needed for heavy or reusable applications. Making the right choice requires a balance of performance, quality assurance, and total cost visibility across the entire lifecycle, not just a focus on upfront price.

Meridian helps businesses evaluate, source, and manage the right pallet solutions through a nationwide supply network, data-driven insights, and quality-controlled manufacturing partners, ensuring better performance and lower overall cost.

If you’re ready to rethink pallet procurement and make smarter material decisions backed by real analytics and savings, connect with Meridian today and discover how much you can improve by choosing the right pallet strategy.

FAQs

Are wooden pallets safe for food and pharmaceutical products?

Yes, wooden pallets can be safely used in regulated industries when they meet hygiene standards and undergo proper heat treatment or kiln-drying. Many food and pharmaceutical operations rely on certified wood pallets that meet specific sanitization and compliance requirements.

How long does a wooden pallet typically last in regular industrial use?

Lifespan varies widely depending on handling conditions, environment, and load type. In well-managed closed-loop systems, a high-quality wooden pallet can complete multiple cycles before needing repair or replacement.

Can wood pallets be repaired, and does that impact performance?

Most wooden pallets can be repaired using replacement deck boards or stringers. Quality-controlled repair processes ensure that structural integrity and load ratings are maintained, making refurbished pallets a cost-effective and sustainable option.

Are wooden pallets environmentally sustainable?

Wood pallets are one of the most recycled and repurposed transport platforms in the supply chain. At the end of life, they can be converted into mulch, composite materials, biofuel, or remanufactured components, supporting circular economy initiatives.

Do different industries require different pallet specifications?

Yes. Sectors such as automotive, construction materials, retail distribution, chemical handling, and cold-chain logistics often require customized pallet specifications based on product weight, safety standards, and facility equipment compatibility.