Pallet shipping is more than just stacking goods on a wooden frame and calling a transporter; it’s a critical logistical step that impacts cost, safety, delivery time, and customer satisfaction. For manufacturers, distributors, and logistics operators, how you prepare, pack, and ship pallets can influence freight costs, damage rates, and overall supply-chain efficiency.

In this blog, we’ll explore what pallet shipping involves, the methods available, best practices for safe and efficient delivery, and how innovative procurement and logistics planning can save you money and headaches down the line.

Quick look

Pallet shipping involves transporting goods stacked on pallets via freight services such as LTL, FTL, and 3PL carriers, as well as international shipping.

It is used for bulk, heavy, oversized, or industrial shipments that cannot be handled by standard parcel shipping.

Proper pallet preparation ensures correct pallet strength, even load distribution, and secure wrapping/strapping, preventing damage and reducing freight costs.

Pallet shipping costs depend on weight, dimensions, freight class, handling requirements, distance, and value-added services.

Choosing between LTL and FTL depends on shipment size, delivery speed, and cost priorities.

Partnering with Meridian supports safer, cost-efficient pallet shipping through compliant pallet supply, packaging optimization, and logistics-aligned procurement expertise.

What Is Pallet Shipping, And When Do You Need It?

Pallet shipping refers to transporting goods loaded onto pallets, typically wooden platforms, via freight services rather than standard parcel or courier shipping. This method is necessary when cargo exceeds the size, weight, or handling limits of regular parcel carriers, or when you’re shipping bulk, heavy, or palletized goods between warehouses, distributors, or end customers.

You need pallet shipping when:

Shipments are bulky, heavy, or irregularly shaped, such as furniture, machinery, bulk retail goods, or palletized inventory.

Goods are headed to a warehouse, distribution center, or commercial facility rather than a typical residential address.

You’re coordinating full pallet loads (full-truckload / FTL) or consolidating them into partial loads (less-than-truckload / LTL).

Logistics efficiency, handling safety, and damage prevention are priorities, for example, in B2B orders, industrial supply chains, or export/import operations.

Pallet shipping ensures that goods are stable, stackable, and protected during transport, making it the backbone of most industrial and distribution supply chains.

Common Methods of Pallet Shipping

There are several standard freight/shipping methods used for palletized goods, each suited to different shipment profiles:

Less-Than-Truckload (LTL): Used when your pallet shipment doesn’t occupy a full truck. Multiple customers’ freight is consolidated, which can be cost-effective but may involve more handling (higher risk of damage) and longer transit times.

Full Truckload (FTL): Employed when you have enough goods to fill a truck (or when you prefer exclusive use). Offers faster transit and lower per-unit cost, with reduced handling and lower risk of mishandling.

Freight Forwarders / 3PLs: Useful for complex shipping, for instance, combining different product types, coordinating multi-modal transport (truck + rail + sea), or handling export/import logistics.

International/Export Shipping: When pallets cross borders, compliance with packaging standards (e.g., heat treatment, fumigation, ISPM regulations), customs declarations, and secure load bracing is vital.

White-Glove / Specialized Delivery Services: For high-value, oversized, or fragile goods that require extra care (e.g., skid unloading, inside delivery, lift-gate services, or specialized handling equipment).

Understanding these methods helps you pick the most appropriate shipping channel based on volume, handling requirements, cost constraints, and destination.

How to Prepare Pallets for Safe and Cost-Effective Shipping

Shipping pallets properly is as important as choosing the correct shipping method. Poorly prepared pallets lead to damaged goods, delayed shipments, and unexpected costs. Key considerations for safe pallet shipping include:

Correct pallet wood & build: The pallet should be built to support the load reliably; use softwood for lighter loads/one-way shipment; or hardwood or reinforced pallets for heavier loads or multiple reuse cycles. Pallet strength and stability are foundational to safe transport.

Even load distribution & weight limits: Goods must be evenly distributed on the pallet surface; overhanging loads or uneven weight distribution can lead to tipping or shifting during transport. Be aware of pallet and forklift capacity limits.

Proper securing and containment: Shrink-wrapping, strapping, banding, or corner boards may be necessary to prevent load movement. Fragile or uneven items might need additional stabilization (e.g., blocking, bracing, cushioning).

Pallet dimensions and pallet count: Accurately define pallet size, height, and footprint, especially for LTL shipments where freight class (and cost) depends on dimensions, not just weight.

Compliance and documentation (for export): If shipping internationally, ensure pallets comply with regulations (heat-treated or fumigated) and include the required marking/labeling, export paperwork, and customs documentation.

Labeling and handling instructions: Clearly label pallets with handling instructions, orientation (e.g., “This Side Up”), weight markings, and contents description to guide carriers and avoid mishandling.

By preparing pallets thoughtfully, you reduce the risk of damage, avoid freight disputes or penalties, and often lower overall shipping costs.

Cost Drivers in Pallet Shipping - What to Watch Out For

Several factors influence how much you’ll pay to ship pallets. Understanding them helps you plan and optimize logistics budgets:

Freight class or density: Many carriers use a classification system in which pallet density (weight vs. volume) affects the rate. Light, bulky pallets might cost more per kg than dense, compact ones.

Distance and transit zones: Long-haul or cross-country shipping typically costs more. Crossing regional zones, state boundaries, or international borders adds surcharges.

Handling requirements: Services like lift gate, residential delivery, inside delivery, special equipment (forklifts, cranes), or white-glove handling increase costs.

Pallet size and dimensions: Non-standard pallet sizes or oversized loads may incur dimensional surcharges or require special permits.

Insurance, liability, and damage protection: High-value goods, fragile items, or high-risk routes may require additional insurance or protective packaging, which can increase costs.

Fuel surcharges and demand fluctuations: Carriers often adjust pricing based on fuel prices and seasonal demand peaks, which can influence shipping quotes.

By understanding and planning around these cost drivers, logistics teams can make smarter shipping decisions and avoid expensive surprises.

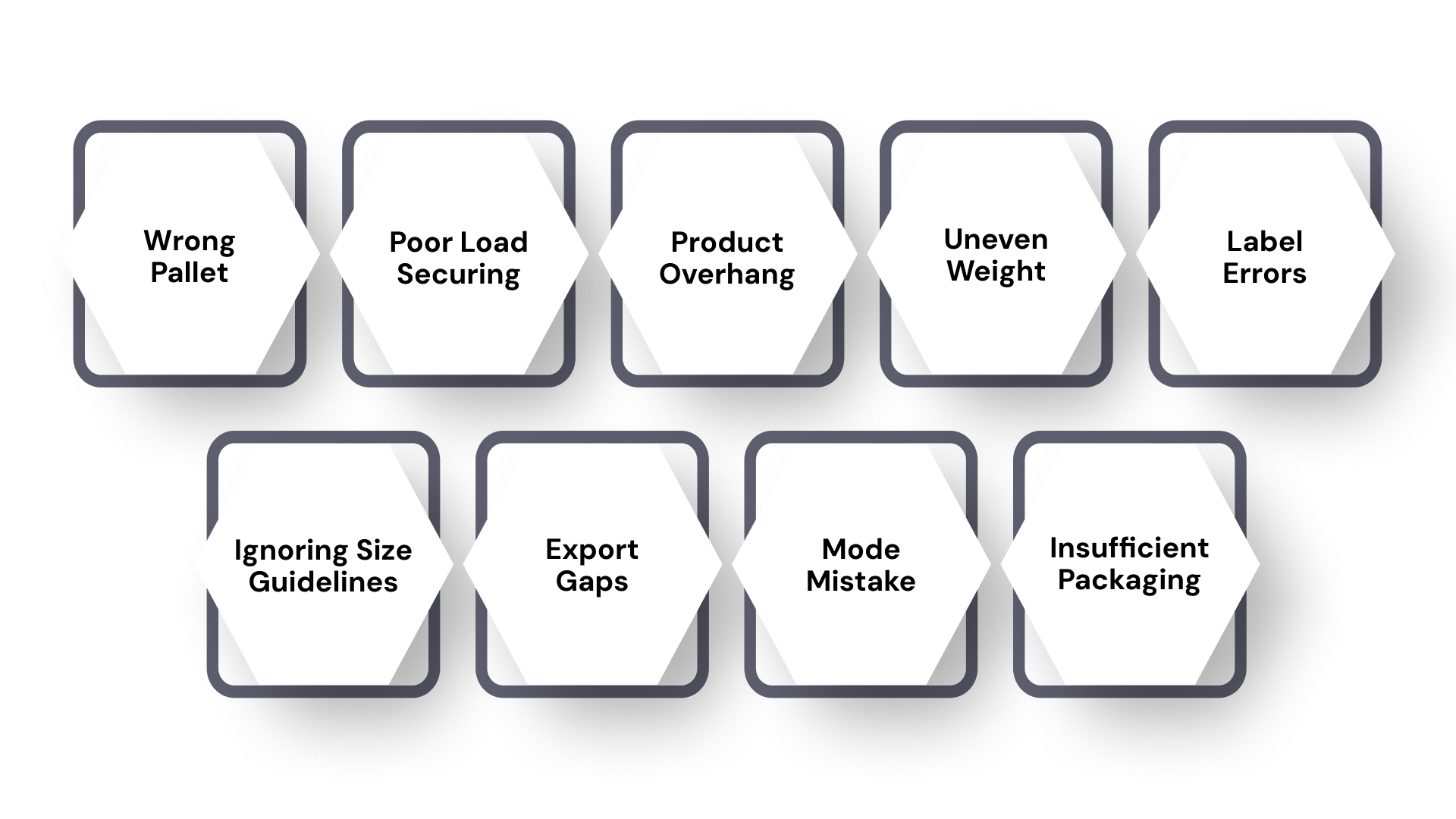

Common Mistakes to avoid in Pallet Shipping

Even well-planned freight shipments can run into preventable problems when pallet preparation or handling processes are overlooked. Some of the most frequent mistakes businesses make during pallet shipping include:

Using the wrong pallet type or insufficient pallet strength for the product weight or handling environment.

Failing to secure the load properly with stretch wrap, strapping, or corner protection can lead to shifting, collapse, or damage in transit.

Allowing product overhang beyond pallet edges increases the likelihood of impact damage during handling or transport.

Uneven weight distribution across the pallet surface, making loads unstable and harder to forklift safely.

Incorrect or missing labeling, causing misplaced freight, handling confusion, or transit delays.

Ignoring size and dimensional guidelines results in unexpected oversize surcharges or reclassification fees from carriers.

Lack of compliance preparation for export, such as missing ISPM-15 heat-treatment markings or incorrect documentation.

Selecting the wrong shipping mode (e.g., choosing LTL when a fragile shipment requires FTL handling).

Insufficient packaging or cushioning for fragile or irregular items that need additional structural support.

Why Meridian Is the Right Partner for Smart Pallet Shipping?

When pallet shipping is mission-critical, especially across multiple facilities, product lines, or logistics routes, having a reliable and experienced supplier is more than convenience; it’s a strategic advantage. Meridian delivers that edge by combining procurement expertise, quality control, and nationwide supply flexibility:

With access to a broad network of manufacturing partners, Meridian can supply pallets built to spec, including heavy-duty hardwood pallets, export-ready heat-treated pallets, and custom sizes.

Their quality-assured pallet builds and packaging audits help ensure that pallets are safe for shipping, correctly packed, and compliant with both domestic and export requirements.

By leveraging aggregated sourcing and a streamlined procurement platform, Meridian helps businesses reduce cost per pallet, improve consistency across locations, and simplify logistics management.

For companies shipping to multiple destinations or using a mix of shipping methods (LTL, FTL, export), Meridian’s capabilities provide flexibility, reliability, and reduced risk of freight damage or rejection, helping you focus on what matters: moving goods efficiently.

Conclusion

Pallet shipping is more than a logistics task; it’s a critical process that shapes costs, efficiency, safety, and customer satisfaction throughout the supply chain. The way you prepare, pack, and choose shipping methods for palletized goods can make or break a shipment’s success.

If you’re ready to elevate your pallet shipping strategy and ensure consistently safe, efficient deliveries, reach out to Meridian, and let us help you streamline procurement, packaging, and freight across your operations.

FAQs

Can pallet shipping work for small-volume orders or single-pallet shipments?

Yes. Many carriers offer LTL (Less-Than-Truckload) services that allow single-pallet or small-volume shipments without requiring a full truckload, provided pallets are prepared correctly and documented appropriately.

Do pallets need to be heat-treated or comply with special regulations for export shipping?

When shipping internationally, many countries require pallets to meet specific phytosanitary standards (e.g., ISPM-15), which require heat treatment or fumigation and proper marking before export.

How can I minimize the risk of damage when shipping pallets long distances?

Use sturdy pallets (appropriate wood type), secure loads with strapping or wrap, distribute weight evenly, avoid overhang, label pallets correctly, and ensure freight is handled by experienced carriers.

Is pallet shipping more expensive than regular parcel shipping?

Yes, pallet shipping typically costs more because it involves freight carriers rather than parcel services. Costs depend on factors such as pallet dimensions, weight, distance, handling requirements, and freight class.

What is the difference between LTL and FTL pallet shipping?

LTL (Less-Than-Truckload) consolidates shipments from multiple customers into a single truck, good for small/partial loads but involves more handling. FTL (Full Truckload) dedicates a whole truck to your load more efficient and safer for larger shipments or fragile items.