While pallets might seem like a small component of your supply chain, poorly managed pallet inventory can have a significant impact on your bottom line. Untracked stock leads to wasted resources, increased costs, and operational delays, all of which slow down throughput and raise risks across your operations.

In this blog, we’ll share practical tips for optimizing your pallet inventory, address the common challenges you might face, and offer solutions to improve cost per unit, reduce downtime, and boost overall efficiency.

Key Takeaways

Effective pallet inventory management helps reduce costs, improve throughput, and boost operational efficiency by keeping track of pallets and optimizing their use.

Common challenges include misplaced pallets, idle stock, pallet damage, and manual tracking errors, which can disrupt operations and increase costs.

Digital tracking (RFID, barcode scanning) provides real-time visibility into pallet movements, reducing errors and improving accuracy.

Key best practices include regular audits, standardizing pallet types, and optimizing warehouse layouts to ensure smoother operations and better use of resources.

By improving pallet management, businesses can reduce downtime, improve lead time stability, and cut costs, leading to a more reliable supply chain.

The Importance of Pallet Inventory Management

Proper pallet inventory management is key to maintaining smooth operations and reducing costs. Pallets are critical for moving goods efficiently, and if they’re not properly managed, they can cause delays, wasted resources, and increased expenses. Here’s why pallet inventory management matters:

Reduces Costs: Accurate tracking and optimal use of pallets help avoid over-ordering and reduce holding costs.

Prevents Stock Issues: Proper management helps prevent stockouts and overstocking, ensuring the right pallets are available when needed.

Improves Efficiency: Clear visibility and organized storage make warehouse operations faster and more efficient.

Supports Compliance and Safety: Proper pallet management ensures compliance with regulations and reduces safety risks.

Boosts Throughput: Efficient pallet management keeps goods moving through your operation faster, reducing downtime.

Without proper pallet management, these benefits slip away, and the challenges that come with mismanagement can quickly go out of control.

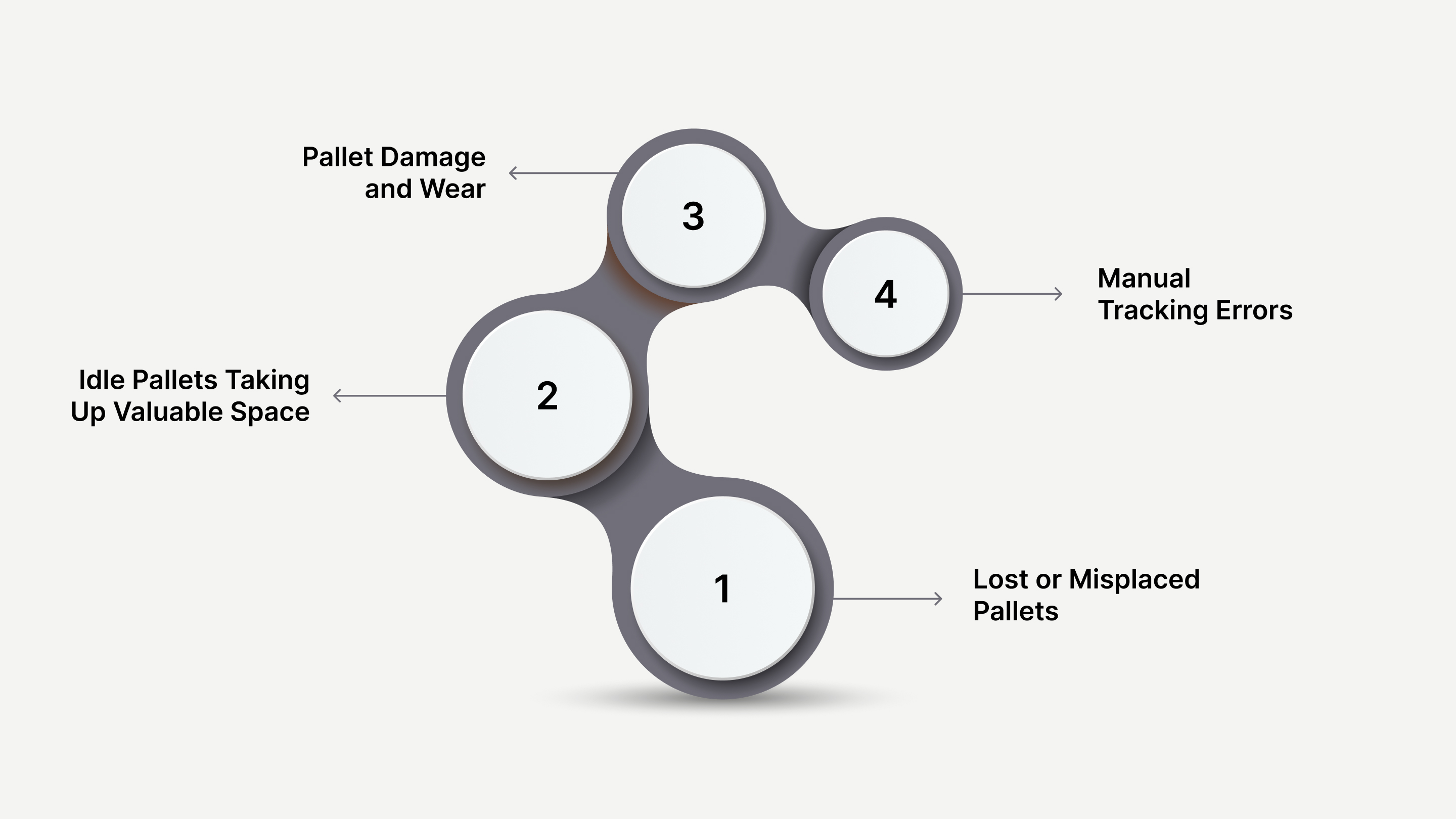

Common Challenges in Managing Your Pallet Inventory

Managing pallet inventory comes with its fair share of challenges, and understanding these obstacles is the first step to gaining control over your operations. Addressing these issues head-on will help you optimize pallet flow, reduce costs, and improve operational efficiency.

Lost or Misplaced Pallets

In busy warehouses, pallets often get misplaced or lost, leading to phantom inventory and inaccurate stock counts. This can result in over-ordering or stockouts, which increase procurement costs and disrupt operations, ultimately leading to lost time and wasted resources.

Idle Pallets Taking Up Valuable Space

Pallets that aren’t being used take up valuable warehouse space, tying up capital and slowing down operations. Idle pallets are a drain on both physical space and financial resources, causing unnecessary holding costs and making it harder to optimize your storage.

Pallet Damage and Wear

Over time, pallets can become damaged or worn down. This increases scrap rates and safety risks, as damaged pallets may lead to product damage or injury. Pallet wear can also result in costly delays, downtime, and the need for more frequent replacements.

Manual Tracking Errors

Relying on manual tracking methods, such as spreadsheets or paper logs, increases the chance of human error. This makes it difficult to track pallet movements accurately, which can lead to incorrect stock levels, lost pallets, and delayed shipments.

You’re here because you’ve likely faced at least one of these challenges in your pallet inventory management, and we get it, it’s a struggle. But don’t worry! We’ve got solutions for you. Keep reading to discover the core practices you can implement to overcome these challenges and take control of your pallet inventory today.

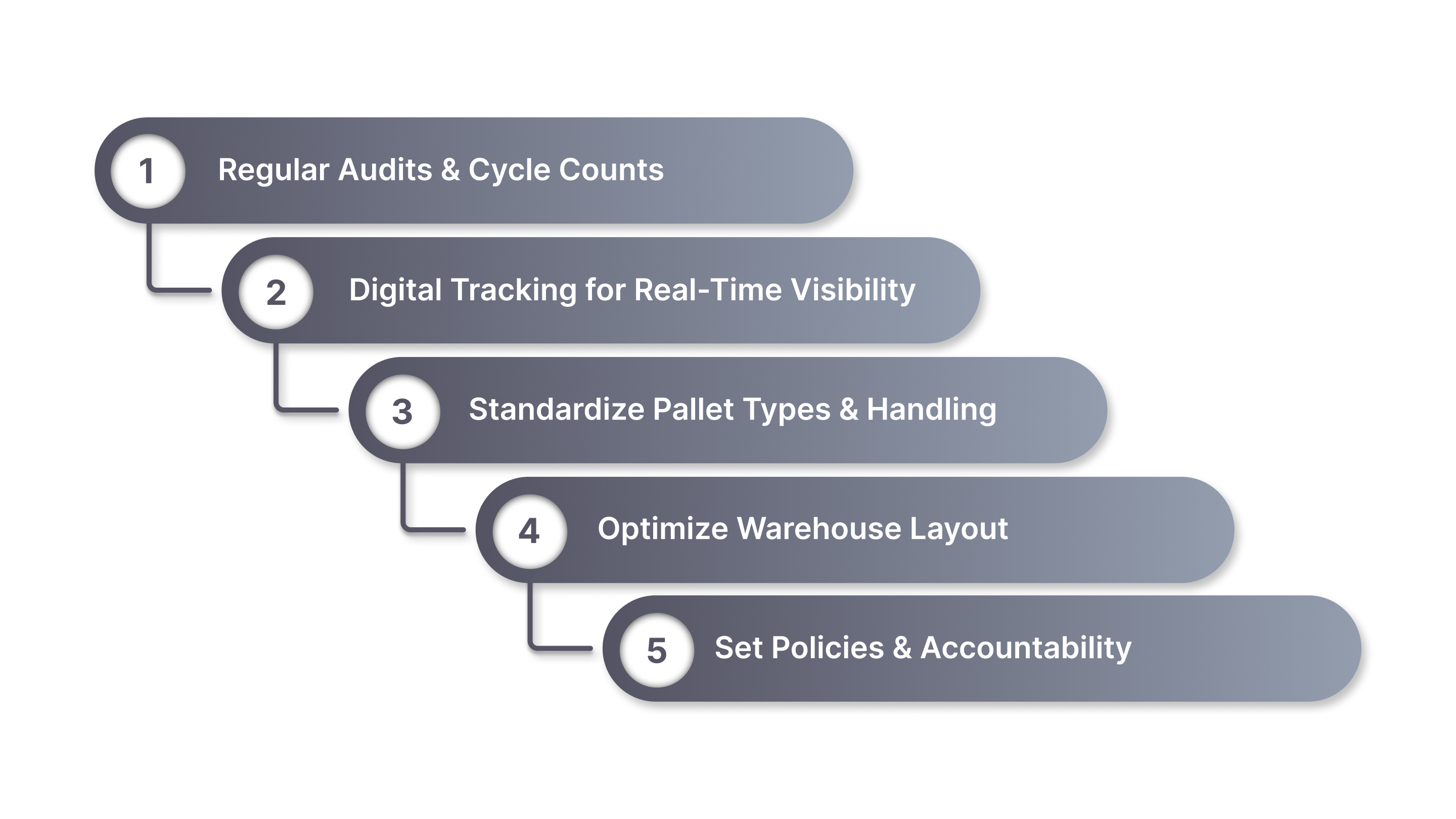

Most Effective Pallet Inventory Management Techniques

Managing pallet inventory can be complex, but adopting the right techniques can help you overcome common challenges and drive tangible improvements. Here are some effective techniques to help manage pallet inventory:

Conduct Regular Audits and Cycle Counts

Regular audits or cycle counts are essential to ensure your pallet stock is accurate and up-to-date. Instead of waiting for a full inventory check, conducting smaller, more frequent audits helps prevent errors and discrepancies that can lead to over-ordering or stockouts.

Regular audits help catch discrepancies early, preventing bigger issues down the line. With accurate stock data, you can avoid unnecessary purchases and reduce waste.

Implement Digital Tracking for Real-Time Visibility

Switching from manual tracking to a digital system, such as barcode scanning or RFID, gives you real-time visibility into your pallet stock. This helps you track pallet movements, monitor their condition, and know exactly where your pallets are at all times.

Digital tracking reduces manual errors and ensures you have accurate, up-to-date data to make informed decisions, saving both time and money.

Standardize Pallet Types and Handling Procedures

Standardizing pallet types and the way they’re handled across your operation reduces confusion and minimizes the risk of mistakes. When everyone follows the same procedures for stacking, storing, and moving pallets, the process becomes more efficient and consistent.

Standardization improves space utilization and reduces pallet damage, leading to fewer replacements and more efficient operations.

Optimize Warehouse Layout for Pallet Flow

A well-organized warehouse layout is crucial for managing pallet inventory. By designing a layout that ensures smooth pallet flow from receiving to storage to shipment, you reduce bottlenecks, save time, and improve overall throughput.

An optimized layout ensures pallets are easy to access and retrieve, helping speed up processes and avoid delays.

Set Clear Policies and Assign Accountability

Setting clear policies for pallet management and assigning accountability ensures everyone in your team knows their responsibilities. When there is a designated person or team responsible for tracking, returning, and maintaining pallets, the process becomes more structured and reliable.

Clear policies reduce confusion, ensure consistency, and help prevent the loss of pallets, improving overall asset management.

By implementing these core practices, you can gain better control over your pallet inventory, reduce operational inefficiencies, and drive cost savings.

Need Better Control Over Your Pallet Procurement?

Meridian’s Procurement Insights Dashboard helps you gain full visibility into your pallet spend and supplier performance, making it easier to manage costs and optimize procurement.

Real-World Use Cases: How These Practices Improve KPIs

Numerous research and industry reports demonstrate the tangible benefits of adopting effective pallet inventory management practices.

Here are a few examples of how these practices can enhance key performance indicators (KPIs)

1. Enhanced Inventory Accuracy | Implemented RFID and barcode scanning for real-time digital tracking | Improved inventory accuracy, reduced pallet loss, and optimized throughput. |

2. Simplified Operations | Standardized pallet types across multiple sites and optimized handling/storage procedures | Reduced downtime, improved lead time stability, and maintained smoother product flow. |

3. Space Utilization & Waste Reduction | Optimized warehouse layout and implemented FIFO pallet tracking during peak seasons | Increased space utilization, reduced waste, and handled higher volumes with fewer resources. |

These use cases show how effective pallet inventory management can improve your operations. By using digital tracking, standardizing pallets, and optimizing warehouse layouts, businesses can reduce downtime, improve throughput, and lower costs, leading to a more efficient and reliable supply chain.

Final Thoughts

Effective pallet inventory management plays a key role in improving your warehouse operations. By addressing common challenges like misplaced pallets, idle stock, and manual errors, and implementing best practices like digital tracking, standardization, and optimized layouts, you can boost throughput, reduce downtime, and cut costs.

If you’re looking to improve your pallet and packaging management, Meridian offers expert solutions through its pallet‑sourcing network. Our services help businesses optimize pallet inventory, simplify procurement, and reduce costs.

Get in touch with Meridian today to learn how we can help you enhance your operations and improve supply chain performance.

Frequently Asked Questions (FAQs)

What is pallet inventory management?

Pallet inventory management involves tracking, organizing, and maintaining pallets in your warehouse or supply chain. It ensures that pallets are available when needed, properly stored, and in good condition, helping to optimize operations and reduce costs.

Why is pallet inventory management important for my business?

Effective pallet inventory management helps reduce costs, prevent stock issues, improve warehouse efficiency, and ensure compliance. It also boosts throughput by keeping goods moving smoothly through your operation, ultimately improving your bottom line.

How can digital tracking improve pallet inventory management?

Digital tracking systems like RFID or barcode scanning give real-time visibility into pallet movement and conditions. This helps reduce manual errors, ensures accurate stock counts, and makes it easier to track pallets, saving time and money in the long run.

What are the most common challenges in pallet inventory management?

Common challenges include lost or misplaced pallets, idle pallets taking up valuable space, pallet damage, and errors in manual tracking. These issues can lead to higher costs, downtime, and delays in operations.

How can I prevent pallet damage and increase pallet lifespan?

To prevent pallet damage, implement regular inspections and maintenance routines. Standardizing pallet handling and using proper storage methods also help reduce wear and tear, extending the lifespan of your pallets and minimizing replacements.