For manufacturers, distribution networks, warehousing operations, and fast-growing e-commerce businesses, pallets are a critical supply chain asset. When pallet shortages occur, production slows, shipments bottleneck, and operational inefficiencies stack up quickly. Yet pallet procurement remains one of the most manually managed and fragmented categories of indirect spend, spread across inconsistent local suppliers, fluctuating pricing, and complex email-heavy purchasing cycles.

To overcome these challenges, many organizations are turning to pallet brokers as strategic supply-chain partners to secure reliable pallet availability, streamline procurement workflows, and lower costs at scale.

Key Takeaways

Pallet procurement is often inefficient and fragmented, causing cost overruns, delivery delays, and operational disruptions.

Pallet brokers centralize sourcing across a large supplier network, ensuring competitive pricing, supply reliability, and flexible fulfillment options.

Brokers typically reduce pallet spend by 10–25% through aggregated buying power and logistics optimization while cutting manual procurement workload.

They offer access to a wider range of pallet types (new, recycled, combo, custom, heat-treated, or specialty), improving operational fit across multiple facility needs.

Partnering with a pallet broker turns pallets from a reactive cost center into a strategic supply chain advantage supported by data, visibility, and scalability.

Who Is a Pallet Broker?

A pallet broker serves as a centralized procurement partner, sourcing pallets from a broad network of manufacturers, recyclers, and specialized providers. Rather than relying on a single supplier, pallet brokers leverage relationships across numerous qualified sources to secure competitive pricing, ensure supply continuity, and offer greater flexibility.

A pallet broker typically provides:

Sourcing for new, recycled, combo, and custom pallets

Supplier vetting and quality assurance standards

Competitive pricing through aggregated volume

Freight and logistics coordination

Local and regional delivery optimization

Centralized ordering, billing & support

Pallet recycling or return programs, where applicable

Put simply, pallet brokers replace the complexity of managing dozens of disconnected suppliers with a streamlined, performance-driven sourcing model.

Why More Businesses Are Choosing Pallet Brokers?

As operational demands increase and supply markets fluctuate, organizations are prioritizing solutions that offer reliability, efficiency, and cost control. This is exactly where pallet brokers excel.

1. Cost Savings & Reduced Administrative Burden

By consolidating buyer demand, pallet brokers secure stronger pricing than most companies can achieve independently, often reducing total spend by 10–25%. On top of that, brokers eliminate hours spent gathering quotes, comparing vendors, and expediting urgent orders.

2. Consistent & Reliable Supply

Supply chain volatility can quickly disrupt pallet availability. A broker’s diversified supplier network reduces this risk, providing built-in redundancy and faster recovery when local or regional supply interruptions occur.

3. Faster Lead Times & Lower Freight Costs

Instead of shipping pallets long distances from a single source, brokers match orders with nearby qualified suppliers, reducing lead times, freight costs, and carbon emissions.

4. Access to a Wider Range of Pallet Types

From GMA 48×40 pallets to ISPM-15 heat-treated export pallets, custom industrial builds, or recycled options, brokers offer tailored solutions to meet specific product or facility needs.

With more flexibility, better pricing, and stronger supply stability, the advantages become clear, especially for organizations operating at scale.

This raises an important question: why not simply purchase pallets directly from a manufacturer or recycler?

Choosing Between Pallet Brokers and Direct Purchasing

Selecting the right approach to pallet procurement can significantly impact supply chain performance. Many businesses begin by buying directly from pallet manufacturers or recyclers, assuming it offers the lowest cost and greatest control. However, direct purchasing often becomes complex and operationally burdensome as demand scales, multiple locations come online, or supply inconsistencies arise.

To determine the best fit, it’s important to understand the practical differences between managing pallet sourcing internally and partnering with a pallet broker.

Buying Direct | Working With a Pallet Broker |

Limited supplier flexibility | Large multi-supplier network |

Higher risk of shortages | Backup supply and contingency coverage |

Manual RFQs and slow quoting | Centralized procurement and automation |

One product type focus | Wide variety of pallet types and grades |

Freight and delivery constraints | Strategic location-based sourcing |

Higher internal labor cost | Reduced admin burden and time savings |

While direct buying may seem cost-effective, it rarely remains so when freight inefficiencies, purchasing complexity, emergency sourcing, or downtime impacts are factored in.

How Technology Is Transforming Modern Pallet Brokerage?

As procurement becomes more data-driven, leading pallet brokers continue to evolve beyond traditional models. A strong example is Meridian, a pallet sourcing and packaging optimization partner that combines industry expertise with advanced software to help businesses reduce cost and increase operational control.

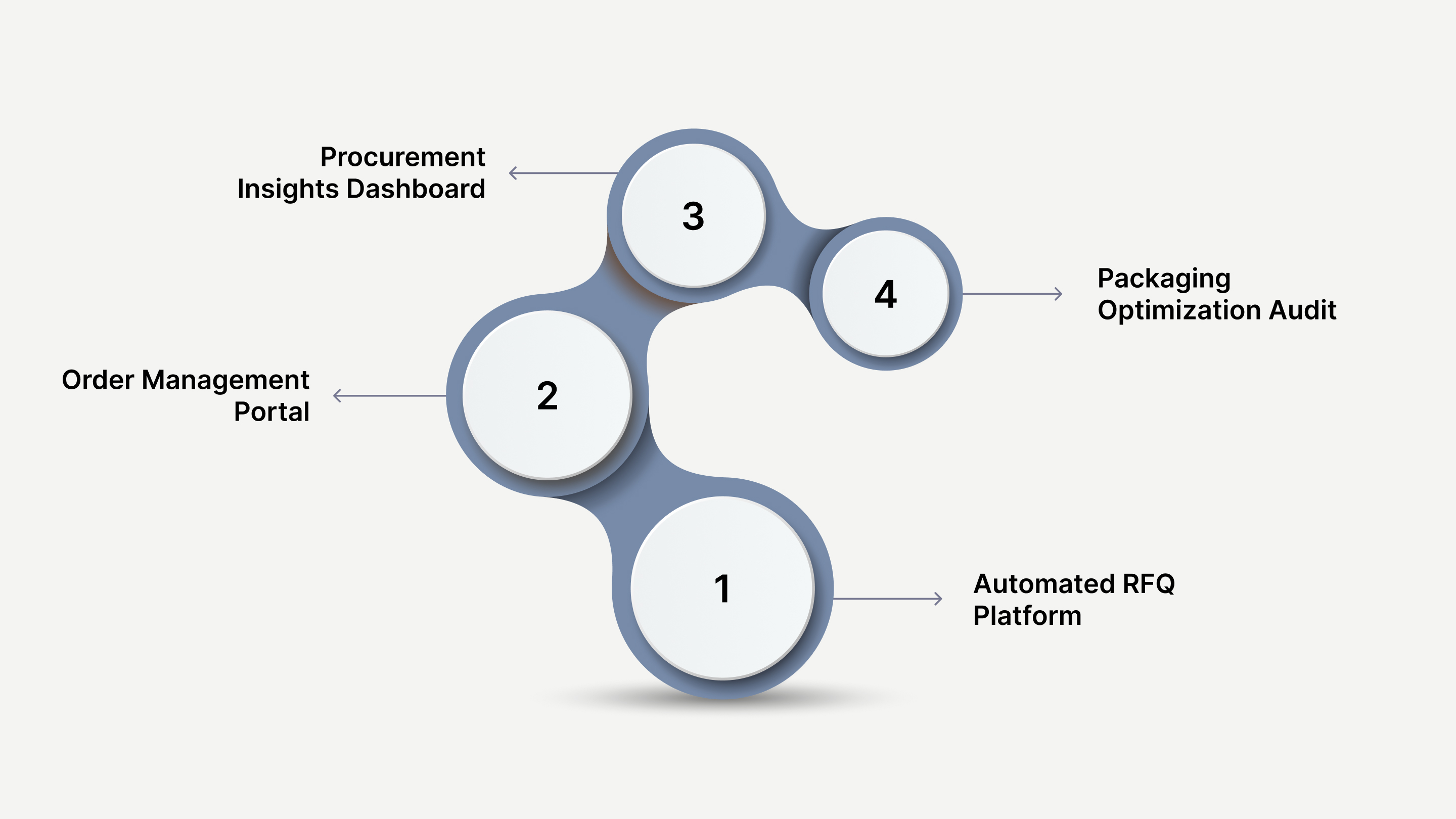

Meridian provides integrated solutions, including:

Automated RFQ Platform

Instantly distribute quote requests to qualified suppliers and compare responses in real time, reducing procurement cycle times by up to 60% and capturing every competitive bid instead of relying on manual outreach.

Order Management Portal

Track shipments, manage invoices, and monitor deliveries from a centralized dashboard, eliminating email chains and spreadsheet chaos while improving supply visibility.

Procurement Insights Dashboard

Turn procurement performance and spending data into actionable intelligence. Identify supplier performance gaps, visualize purchasing trends, and uncover new savings opportunities.

Packaging Optimization Audit

Meridian’s experts analyze packaging specifications to identify waste and redesign requirements to improve efficiency. Many companies discover a 15–30% potential for immediate savings without operational disruption.

These solutions move pallet procurement from reactive and tactical… to strategic, measurable, and technology-powered.

Who Benefits Most from Working with Pallet Brokers?

Pallet brokers deliver significant value for businesses that:

Operate multiple facilities or distribution locations

Experience seasonal or variable demand

Require consistent pallet quality across sites

Are scaling rapidly and need supply flexibility

Want centralized purchasing control with lower internal workload

Aim to reduce the total cost of ownership, not just unit cost

Any organization moving high volumes of product can benefit from greater reliability and cost predictability.

How to Select the Right Pallet Broker?

Transitioning pallet procurement to a broker model is most successful when selecting a partner that offers:

A strong supplier network and sourcing redundancy

Transparent pricing and clear cost structures

Proven on-time delivery performance

Technology-enabled visibility and analytics

Ability to scale capacity quickly

Dedicated communication and responsive support

The right broker should operate as a strategic partner, not simply a reseller.

Conclusion

As demand increases and supply chains become more complex, pallet brokers are reshaping how companies manage pallet procurement. Through improved supply reliability, measurable cost savings, centralized management, and advanced digital visibility, they transform pallet purchasing into a strategic advantage rather than a recurring challenge.

Meridian is helping organizations achieve exactly that, combining the power of a nationwide supplier network with modern procurement technology to deliver speed, transparency, and real financial impact.

Ready to simplify your pallet procurement and discover potential savings?

Schedule a consultation with Meridian to evaluate your pallet and packaging strategy and uncover new opportunities to reduce costs while strengthening supply performance.

FAQs

How do pallet brokers maintain quality consistency when sourcing from multiple suppliers?

Although brokers work with various suppliers, they implement standardized inspection and grading frameworks that ensure consistent pallet specifications regardless of source. This helps maintain performance standards across locations and shipment types.

Can pallet brokers support sustainability initiatives such as pallet reuse or recycling programs?

Yes. Many brokers integrate recycling, repair, and recovery programs to reduce landfill waste and help companies meet sustainability goals. Some even provide reporting metrics for ESG tracking and circular packaging initiatives.

Do pallet brokers support specialty or industry-specific pallet needs?

Advanced brokers often support custom engineering for industries such as food & beverage, pharmaceuticals, automotive, and aerospace, including heat-treatment compliance, sanitation standards, durability upgrades, and load-specific design.

What data or visibility metrics should companies expect from a good pallet broker?

Beyond basic delivery updates, brokers should offer performance dashboards that include order accuracy rates, lead-time trends, supplier reliability scores, and demand-planning forecasting tools.

Is it possible to integrate pallet brokerage technology with existing ERP or procurement systems?

Yes. Many modern broker platforms offer API or EDI connectivity to integrate with ERP systems such as SAP, Oracle, Microsoft Dynamics, NetSuite, or procurement automation tools for seamless operational flow.