Millwood, Inc. is a well-recognized name in the pallet and packaging industry, providing packaging systems, pallets, unit-load solutions, and load-stability products to businesses across the U.S. For many organizations, Millwood has served as a reliable partner for pallet supply and packaging support. However, as supply chain expectations evolve, especially around visibility, multi-location scalability, and digital procurement, more companies are exploring Millwood alternatives to compare capabilities, sourcing flexibility, pricing models, and technology-forward solutions.

Choosing the right pallet or packaging provider has become increasingly important as companies look to reduce operational bottlenecks, lower total supply-chain costs, and strengthen resilience against market fluctuations and material shortages. Evaluating different service models and suppliers helps procurement teams ensure they are aligned with the business's long-term needs, rather than relying on legacy vendor relationships without exploring alternatives.

Key Takeaways

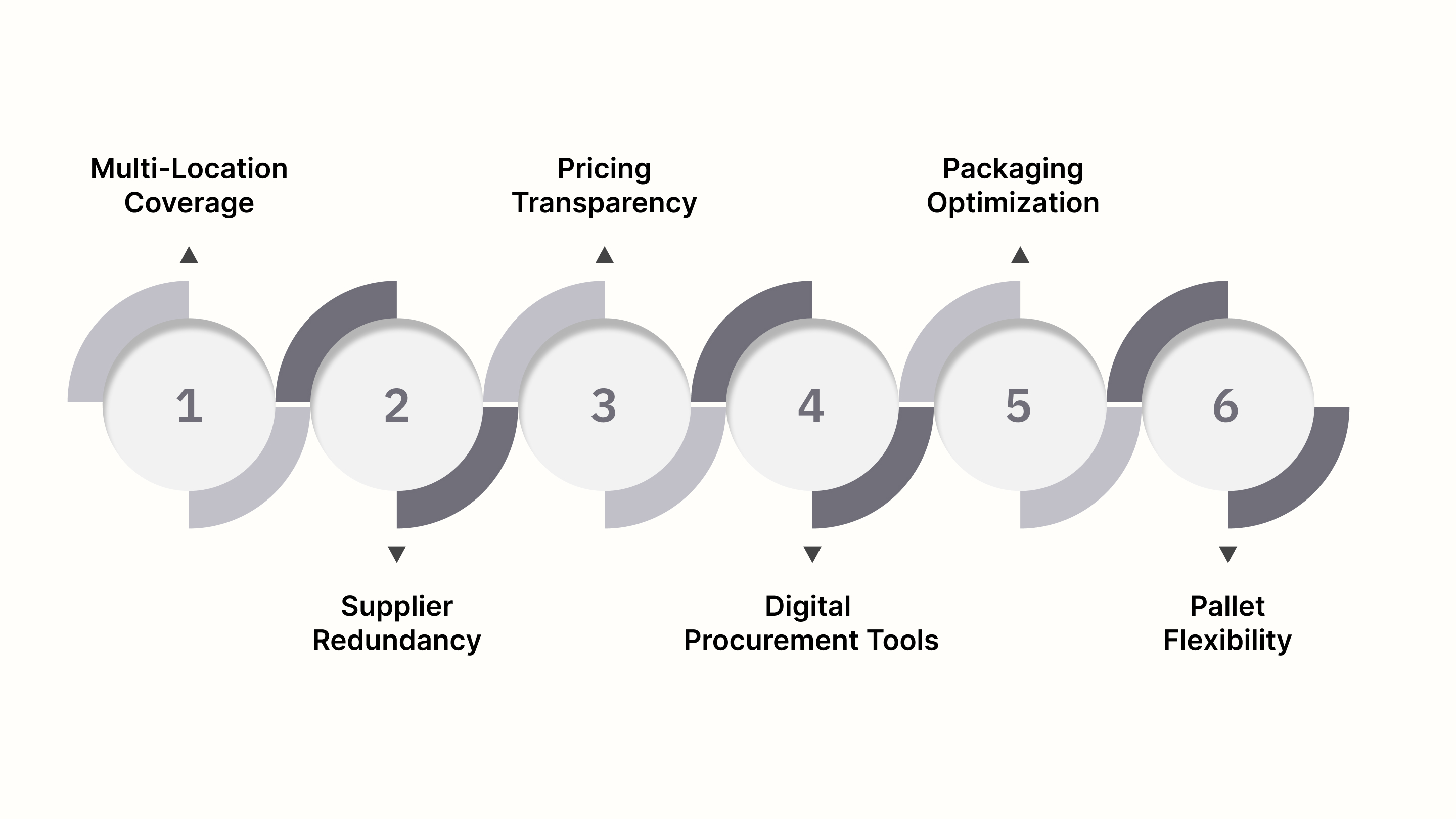

Many organizations consider Millwood alternatives to find better alignment with their evolving needs, such as multi-site supply coverage, scalable sourcing flexibility, stronger pricing visibility, or access to digital procurement tools.

When exploring alternatives, key evaluation criteria include supply network size, technology capabilities, pallet type availability, sustainability programs, and ability to support rapid demand changes.

Common alternative provider types include national pallet suppliers (Kamps, 48forty), pooling networks (CHEP, PECO), new-pallet manufacturers (PalletOne), and network-based procurement partners (Meridian).

The right partner depends on business model and operational priorities. Some companies benefit from recycled pallet networks, others from technology-enabled platforms or closed-loop pooling systems.

A thoughtful comparison can improve cost stability, supply resilience, and procurement efficiency, rather than relying on a single supplier model.

Why Businesses Look for Millwood Alternatives?

Many companies seek Millwood alternatives not because of dissatisfaction, but because evolving supply chain needs sometimes require different levels of flexibility, coverage, or service scope. Common reasons include:

1. Supply Coverage for Multi-Location Operations

Some suppliers have a stronger presence in specific regions, while growing businesses often expand geographically and need seamless coverage across multiple states or distribution locations.

2. Desire for Supplier Redundancy

To avoid dependence on a single supplier, many companies build diversified sourcing models in which multiple providers work together to maintain continuity and stabilize pricing.

3. Need for More Pricing Visibility & Competitive Bidding

Organizations increasingly want transparent procurement workflows with competitive quoting rather than fixed-price ordering that may not reflect current market rates.

4. Growing Demand for Digital Procurement Tools

Modern supply chain operations value platforms that offer real-time tracking, reporting dashboards, and data-based insights rather than manually managed spreadsheets and email orders.

5. Support for Packaging Optimization & Cost-Reduction Programs

Companies looking for engineering support, packaging audits, or savings analysis may explore alternative service providers that can evaluate existing designs and identify improvement opportunities.

6. Flexibility in Pallet Types & Availability

Some providers focus on new pallets, others on recycled, pooled, or custom pallets, depending on the product mix. Companies may look for options beyond what their current supplier can offer.

Once businesses identify the reasons for exploring new options, the next step is knowing which evaluation criteria matter most.

What to Compare When Evaluating Millwood Alternatives?

Before changing pallet suppliers or adding additional partners, it helps to evaluate potential providers using key comparison categories:

Geographic footprint & supply reach

Supplier network redundancy vs single-location production

New, recycled, custom, or specialty pallet options

Digital procurement capabilities (RFQ automation, tracking portals, dashboards)

Packaging optimization expertise & engineering support

Sustainability programs (repair, reuse, recycling)

Lead times, capacity, and service level consistency

Pricing transparency and competitive bidding flexibility

Reporting/analytics needs

Well-structured supplier evaluation ensures alignment with operational and financial priorities rather than making decisions based solely on pallet price per unit.

With key decision criteria established, it becomes easier to explore the different types of providers and specific companies that may serve as viable Millwood alternatives.

Top Alternative Companies & Solutions to Consider

Below are organizations and provider types that businesses often evaluate as alternatives to Millwood, depending on needs, facility footprint, supply chain model, and packaging requirements. Each offers different strengths, trade-offs, and best-fit use cases.

1. Meridian (Flexible Network-Based Pallet Procurement & Packaging Optimization Partner)

Meridian is a pallet procurement and packaging-supply partner operating through a large supplier network rather than a single production infrastructure. This allows businesses to source pallets from multiple providers, reduce risk, and leverage competitive supplier bidding. Meridian also offers procurement technology tools, including automated RFQ distribution, real-time order tracking, centralized dashboards, and packaging optimization audits that help identify system-wide savings opportunities.

Strengths

Flexible sourcing and supplier redundancy

Competitive bidding and pricing visibility

Procurement analytics and shipment tracking

Packaging optimization expertise (15–30% potential savings discovery)

Best For - Companies seeking multi-location coverage, scalable supply, or technology-enabled procurement visibility.

2. Kamps, Inc.

Kamps is one of the largest pallet manufacturers and recyclers in the U.S., with 400+ locations nationwide and a strong footprint in pallet recycling and sustainability. They handle large pallet volumes and operate recycling, sorting, and repair programs for customers looking to reduce landfill waste.

Strengths

Nationwide recycled pallet and reclaimed supply chain

Quick turnaround on standard pallet sizes

Lifecycle services: retrieval, repair, and reuse programs

Best For - Companies prioritizing recycled pallets, environmentally-aligned programs, and reliable large-volume availability.

3. 48forty Solutions

48forty is the largest pallet management services provider in North America, with extensive recycling facilities, transport fleet support, and comprehensive pallet-handling programs. They specialize in pallet recovery, reverse logistics, repair, and full outsourced management programs.

Strengths

National asset-based infrastructure and trucking fleet

Full lifecycle pallet management and reverse logistics

Strong footprint in food, retail, and distribution networks

Best For - Businesses seeking one-vendor pallet management with recycling and retrieval efficiency.

4. CHEP (Pallet Pooling / Rental Model)

CHEP operates a pallet pool rental system in which companies rent reusable pallets rather than purchasing them. Pallets are returned, repaired, and re-circulated through the LOOP system.

Strengths

Rental model eliminates pallet ownership responsibility

High-quality, standardized reusable pallets

Environmental and sustainability benefits

Best For - Retail, consumer goods, and closed-loop shipping environments where pallet return is manageable.

5. PalletOne

PalletOne is a major manufacturer of new, custom, and standard wood pallets, with lumber capabilities and experience in specialty-engineered pallet design.

Strengths

Consistent quality and structural performance

Custom pallet engineering and ISPM-15 export pallets

Strong option when recycled pallets are not suitable

Best For - Industrial manufacturing, export shipping, or heavy-load environments.

6. PECO Pallet

PECO Pallet provides red block pallets and reusable pallet pooling services similar to CHEP but often favored in grocery, wholesale, and dry-goods distribution.

Strengths

High standardization and durability

Well integrated with major retail distribution networks

Best For: Retail supply chain networks that need unified pallet flow.

7. Independent Regional Pallet Recyclers & Custom Builders

Across the U.S., there are hundreds of local pallet suppliers, often used for regional delivery, custom-dimension builds, or urgent spot orders.

Strengths

Lower freight costs for nearby facilities

High responsiveness and faster turnaround

Flexibility for small or special-order pallets

Best For

Single-site operations or operations located near urban industrial markets.

These companies represent a diverse landscape of pallet and packaging solutions, each tailored to different business priorities. To simplify comparison, it helps to group Millwood alternatives into provider categories based on how they source, service, and support customers.

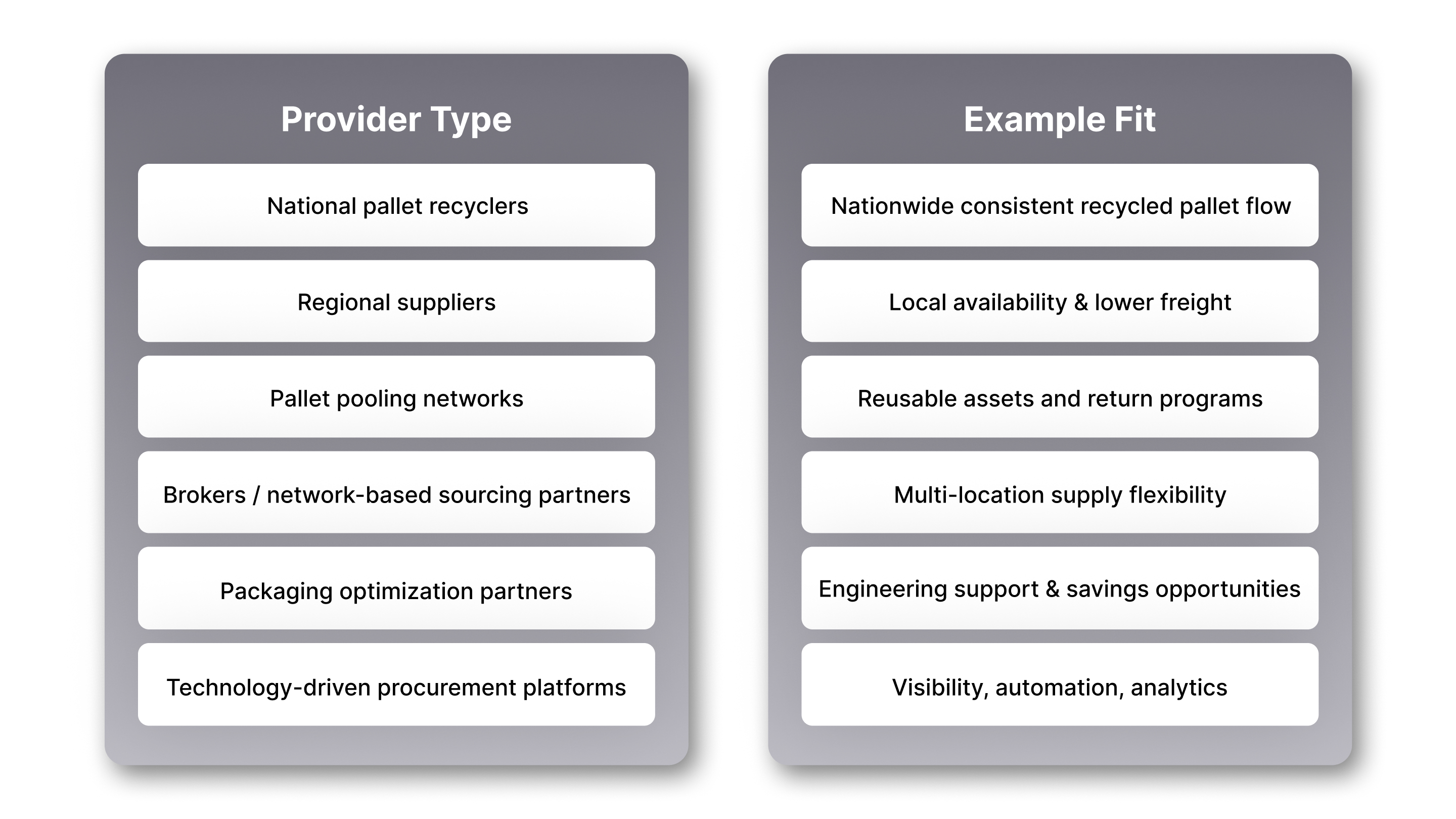

Types of Millwood Alternatives to Consider

Not every business needs the same type of provider. Common models include:

Provider Type | Example Fit |

National pallet recyclers | Nationwide consistent recycled pallet flow |

Regional suppliers | Local availability & lower freight |

Pallet pooling networks | Reusable assets and return programs |

Brokers / network-based sourcing partners | Multi-location supply flexibility |

Packaging optimization partners | Engineering support and savings opportunities |

Technology-driven procurement platforms | Visibility, automation, analytics |

With a clearer view of potential partners and provider categories, the final step is determining which alternative aligns most effectively with your organization’s goals.

How to Choose the Right Alternative?

The best fit depends on operational needs, supply footprint, reliability expectations, and how well a provider aligns with long-term growth plans. Evaluating partners through a strategic lens helps ensure the decision supports both immediate requirements and future scalability.

Demand stability vs seasonal spikes

Load sensitivity and QA standards

Sustainability requirements

Cost transparency and bidding competitiveness

Multi-location vs single-site operations

Internal resources to manage suppliers

It often makes sense to conduct a side-by-side comparison, pilot trial, or cost-benefit evaluation before selecting the final long-term model.

Conclusion

Millwood is a respected player in the pallet and packaging space, but the logistics landscape today presents more options than ever. Exploring Millwood alternatives can help companies improve cost efficiency, supply resilience, sustainability performance, and visibility into procurement operations. Providers such as Meridian, Kamps, 48forty, CHEP, PalletOne, PECO, and many regional suppliers each offer distinct strengths tailored to specific business needs.

Finding the right fit isn’t about replacing a supplier; it’s about building a stronger sourcing strategy with the flexibility to support growth and operational stability.

If your team is considering additional pallet sourcing strategies or evaluating ways to optimize packaging and procurement processes, working with a consultative partner like Meridian can help assess savings opportunities and build a scalable supply approach.

Contact us today to know more about our products.

FAQs

How do I know whether switching or adding an additional pallet provider is necessary?

Look for signs such as inconsistent pallet availability, frequent lead-time issues, unpredictable pricing changes, or operational strain caused by supplier limitations. If your needs are outgrowing your current supplier’s structure, evaluating alternatives may be beneficial.

Is it common for companies to work with more than one pallet provider at the same time?

Yes. Many organizations diversify supply through hybrid sourcing combining national suppliers, brokers, pooling networks, and regional recyclers to minimize supply risk and improve pricing leverage.

Will diversifying pallet suppliers increase administrative workload?

Not necessarily. Many non-asset brokers and procurement platforms consolidate ordering, invoicing, and supplier communication into a single channel, reducing internal management time rather than increasing it.

How long does it typically take to transition or onboard an additional pallet supplier?

Depending on order volume and geographic footprint, transitions can range from days to a few weeks. Phased onboarding or pilot tests are common to ensure a smooth changeover without disrupting existing supply.

Can alternative pallet providers support sustainability goals such as recycling and waste reduction?

Yes. Many alternatives offer pallet repair, recovery, reuse programs, and recycled-material options to reduce landfill waste and support circular packaging initiatives.